Alternate Tool Material For Hogging Large Workpieces

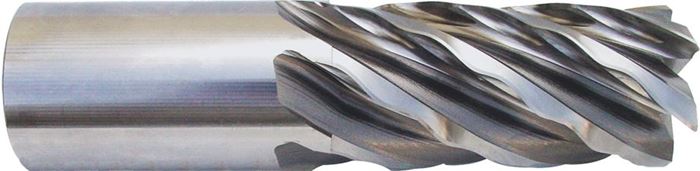

Shops often use either carbide or high speed steel cutting tools for hogging out the large workpieces common to the aerospace and moldmaking industries. While both materials have their advantages and disadvantages, cutting tool manufacturer Precision Cutting Tools says powder metal combines the best features of both.

Share

Attaining high metal-removal rates is a priority for many manufacturers, especially those serving the aerospace and moldmaking industries. Although carbide and high speed steel (HSS) cutting tools are popular for roughing applications on the large components common to such shops, both have disadvantages, notes Ivan Salazar, marketing manager for Santa Fe, California-based Precision Cutting Tools (PCT). He says roughing with carbide tools can be difficult because carbide can be somewhat brittle, chipping and breaking at high feeds and speeds. And while HSS is less prone to chipping, it can soften and wear at the high temperatures generated by heavy cuts, especially in applications involving titanium and other exotic alloys that have low heat-transfer rates.

PCT offers another alternative. Mr. Salazar says powder metal tools combine the best features of carbide and HSS. According to Mr. Salazar, powder metal can outperform both materials in rough-milling applications where the goal is to hog out as much metal as possible as quickly as possible.

Compared with HSS, powder metal provides higher heat and wear resistance, lasts longer and is only moderately more expensive, Mr. Salazar explains. Carbide, on the other hand, is harder than powder metal, making it the better choice for finishing applications in which the goal is to produce the smoothest possible surface. However, carbide’s extreme hardness makes it more susceptible to shock. Powder metal is more flexible, allowing users to run at higher feeds and speeds without worrying as much about breaking the tool. Additionally, powder metal tools are less expensive than their carbide counterparts, Mr. Salazar says.

Powder metal’s advantages stem primarily from the fact that its composition is designed to reach a fine balance between hardness (the material’s resistance to chipping or breakage) and toughness (the material’s resistance to gradual wear). Each tool consists of a soft matrix that acts like a glue to hold carbide cutting particles together, says Dave Reau, PCT’s quality control manager. Because the matrix is softer than the carbide particles, the volume of matrix versus the volume of carbide determines the tool’s hardness and toughness characteristics.

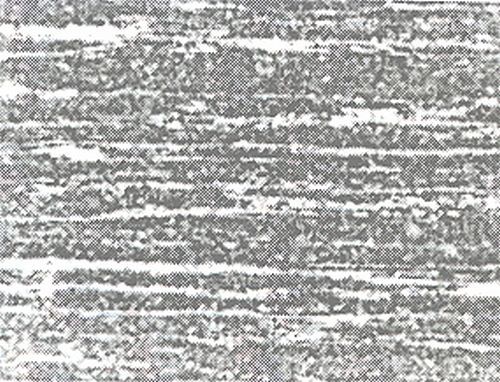

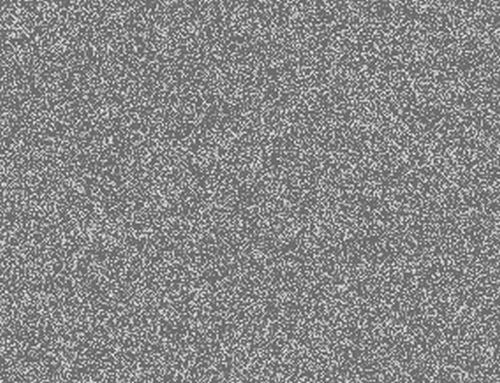

Powder metal tools are less brittle than their carbide counterparts because the matrix volume is greater than the carbide volume, while this relationship is reversed in most carbide tools, Mr. Reau notes. He says the tools are more wear-resistant than their HSS counterparts because the carbide particles are more uniformly distributed. This is beneficial because fractures can move through the tool more readily if the carbide particles are aligned, which is common in conventional HSS, he adds.

"Under a microscope, powder metal looks like sand—it mixes together quite finely." Mr. Salazar explains. "Conventional HSS, on the other hand, looks like veins of wood. It’s not quite as compressed and not quite as homogenous."

Powder metal tools can be used for workpieces ranging from aluminum mold cavities to large aerospace components made of titanium, Waspalloy, Hastalloy and other exotic alloys. Materials in the powder mixture are carefully proportioned according to each tool’s intended application. For example, PCT’s PM 30 and PM 60 series contain higher percentages of cobalt for machining hard materials, whereas the company’s PM 4 line includes more vanadium for aluminum workpieces.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=300;quality=90)