Die/Mold

The Case for Software-as-a-Service ERP

The owner of a die manufacturing business describes why he prefers to subscribe to ERP software rather than buying it.

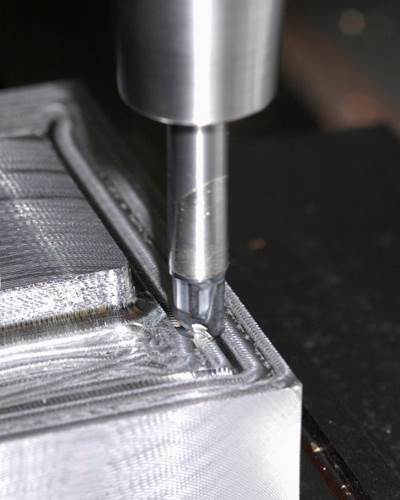

Read MoreVideo: Hard Pocket Milling

Relieved end mills and pre-machining of corners are two important considerations for accurate pocket machining in hard steel.

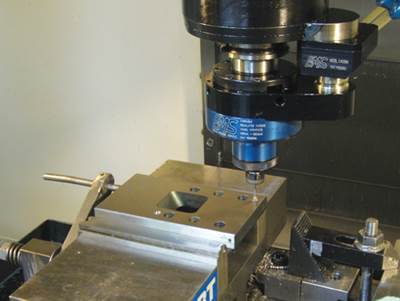

WatchIndexable Mills Speed Cavity Cutting

Ballnose mills are a common choice for hogging out cavities on molds and form dies. However, these three shops have realized significantly faster cavity milling by switching to Ingersoll’s Chip Surfer modular tooling system, which features a cylindrical shape that keeps more of the tool engaged in the cut.

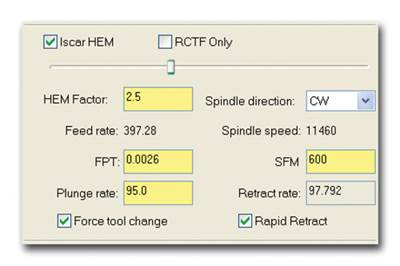

Read MoreSoftware/Tooling Partnership Promises Easier HSM

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read MoreFind Your Speed Outside of Machining

This short-lead-time mold shop achieves its most significant time savings by looking outside the machining cycle. However, one of those elements outside the cycle—palletized setup—ultimately led to cycle time savings via five-axis machining.

Read MoreVideo: Minimizing Mistakes with Laser Scanning CMM

Die Tech & Engineering uses its scanning to CMM to avoid errors by inspecting electrodes prior to EDM.

WatchMilling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

WatchHow to Overcome an Acc/Dec Limitation in High Speed Machining

A small pocket in a graphite workpiece limits productivity. Part of the expert’s response is to consider how a lower feed rate might actually be more productive—because the machine will spend more time at the programmed rate.

Read MoreFinished Molds Overnight

In the highly competitive athletic footwear market, moving from concept to design to production at breathtaking speed is imperative. Fast and efficient five-axis machining is a key accelerator in this process.

WatchVideo: 3+2 Mold Machining at Eifel

A maker of injection molds for high-appearance-quality parts describes the machine tool, software and strategy this shop uses to apply 3+2 machining.

Watch