Aerospace

High Speed Machining's Origin Moment

An important episode for high speed machining illustrates one of the most underappreciated aspects of the value of manufacturing.

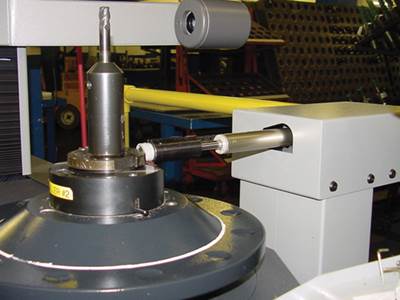

Read MoreDial Down or Dial Up?

Vibration analysis may be the machining center’s missing piece. If you haven’t performed this analysis on your high speed machine, you probably don’t know what the machine can do.

Read MoreThe Promise of "High Cube" Machining

Tool paths and a new tool design provide an alternative to high speed machining for achieving high metal removal rates in hard metals on lighter-duty machines.

Read MoreVideo: Milling Inconel 718 Efficiently Without a Heavy Machine

This video of machining Inconel at a fast metal removal rate shows the effect of constant-engagement-angle milling.

WatchVideo: Milling Titanium 6-4 Efficiently Without a Heavy Machine

This video of machining titanium at a fast metal removal rate shows the effect of constant-engagement-angle milling.

WatchMachine-Ready Blanks Save Time

According to the supplier, its machine-ready blanks reduce overall part costs.

Read MoreTool Certainty

For GKN Aerospace to overcome tool-related variations on its largest milling machines, it had to confront error sources that go unnoticed in many shops.

Read MoreShifting Gears To Integral Drive Adds Productivity

Machines with geared-head spindles are typically employed for machining titanium and other tough materials that require high torque. However, replacing such models with integral-drive HMCs from Makino has enabled this contract manufacturer to significantly improve productivity on time-sensitive aerospace jobs.

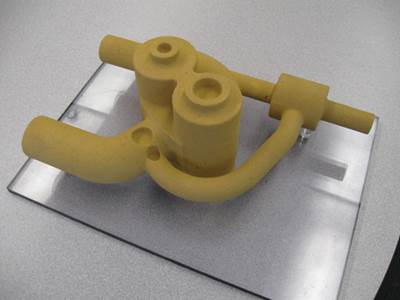

Read MoreStraight to Sand

Through direct CNC machining of molds and cores, this supplier of cast and machined parts skips the pattern-making step that would otherwise be fundamental to casting. The result is weeks of lead-time savings for complex parts that are needed in a hurry.

WatchWhat Is The Right Machine Tool For Titanium?

Rather than start with the machine, says Boeing, start with the tooling. For titanium workpieces and other high-value parts, a simple spreadsheet of tools and operations might be the most valuable resource for machining center selection.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)