Aerospace

Tool Line Complements Titanium, Stainless Techniques

A notable trend over the past five years or so has been the evolution of techniques for machining hard, difficult-to-cut materials, particularly titanium and stainless steel.

Read MoreWater Conservation in Waterjet Machining

This job shop’s water reclamation system also extends the life of waterjet machine hardware.

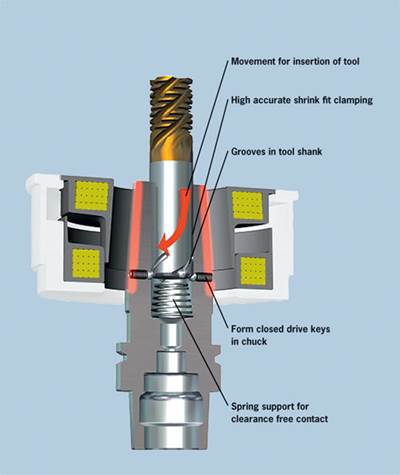

Read MoreTitanium Calls for a Tight Hold on the Tool

Haimer’s SafeLock System provides pull-out protection for tools in high performance cutting such as the machining of titanium.

Read MoreBriquetter Alleviates Chip Disposal Inefficiencies

When this manufacturer of aircraft ejector seats increased its machining capacity, the volume of chips generated increased as well. A briquetter from Prab provided a safe work environment, a fast return on investment and cost savings that have added to the shop’s profitability.

Read MoreMaking Research Real

Rolls-Royce expands upon a successful formula for developing manufacturing innovations beyond university research and into production.

Read MoreComposites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

Read MoreSix Ways Outsourced Maintenance Saves

Outsourcing maintenance to a third-party specialist can be a cost-effective way to realize higher overall equipment efficiency and better process control.

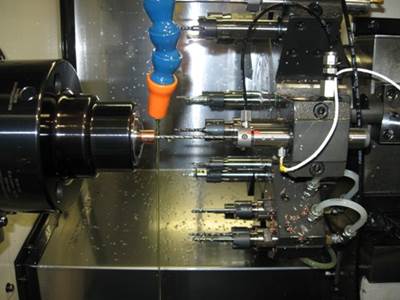

Read MoreDrilling with Modulation Delivers Pecks for Free

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

WatchTaking on Titanium

The challenge for the aerospace machine shop is to produce titanium parts productively and profitably. The challenge for the machine tool builder is to help such shops meet this challenge.

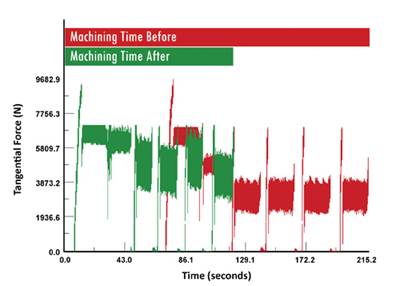

Read MoreBalanced Machining Is Faster Machining

NC program optimization software initially helped Bell Helicopter’s Drive Systems Center machine titanium faster by balancing cutting forces. The manufacturer now uses it to improve cycle times for aircraft parts made from other metals, too.

Read More

.jpg;maxWidth=970;quality=90)