Aerospace

ERP Synergizes Disparate Departments, Applications

Despite access to a sophisticated ERP system, this company still used manual methods for managing critical resources. Expanding its use of that system has streamlined operations and synergized disparate software applications and departments.

Read MoreLong-Lasting Insert Turns Around Tough Inconel Job

By changing to a hex-shaped turning insert with a 45-degree lead angle, this shop saved thousands of dollars on a difficult Inconel turning application.

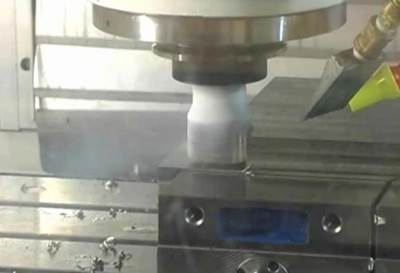

Read MoreVideo: Cryogenic Machining of Titanium

Through-tool liquid nitrogen turns the tool into a heat sink, extending tool life.

WatchVideo: Machining Long Parts Through a Small Machining Center

Video from Chiron America demonstrates the company’s Multi-Profile System, which combines a machining center with in-feed and out-feed accessories so that the compact machine can mill and drill long parts.

WatchThe 400° Difference

Cryogenic machining achieves dramatic tool life gains not by flooding the cut, but by refrigerating the tool.

Read MoreZayer Sizes Up the Large Machine Market

Republic Lagun Machine Tool Co. is promoting this line of traveling column machines to users in the wind turbine, airframe, oilfield and rail industries.

Read MoreLet the Tool Path Help the Tool

A cutting tool supplier works in CAM software to create processes that extend tool life and improve performance.

Read MoreOne Way to Machine Long Titanium Parts

This horizontal machining center design not only addresses the need for larger machining capacity for long aerospace components, but it also offers impressive material removal rates for tough titanium alloys.

Read MoreCAM Features Facilitate Five-Axis “Hog-Outs”

A point of pride for this shop is its ability to take on projects others wouldn’t touch. Recently, capabilities within Mastercam CAM software enabled the company to overcome challenges with a difficult aerospace component and, more significantly, to bring in new, similar work.

WatchPresetting Process Cuts Scrap, Rework

Aerospace manufacturer Fokker Aerospace Group relies on Speroni’s STP46 tool measuring and presetting machine to ensure that step drills used to cut and chamfer holes on aircraft flap skins are within tolerance and set to the proper length. This machine and custom procedures developed by Speroni enables the aerospace manufacturer to avoid cost and downtime resulting from reworking or scrapping these large parts.

Read More