Aerospace

How Do You Stop A Thin Aluminum Workpiece From Curling?

The material condition is more likely to be the culprit than any particular choice at the machine tool.

Read MoreWhat is the Best Process for Micro-Deburring?

Various techniques address the challenge of getting a clean machined feature at microscopic scales.

Read MoreWhat Is The Best Way To Machine A Deep, Narrow Pocket In Titanium?

Boeing’s answer to a reader question emphasizes the use of high-feed milling tools.

Read MoreHow Limiting Are Limited Five-Axis Travels?

Boeing experts recently responded to a question regarding a “nutating” head that was submitted through our Aerospace Machining Zone

Read MoreMicromachining: Drilling Is Doable

This shop drills 0.020-inch holes as part of a machining cycle that also includes full-size tools cutting full-size features.

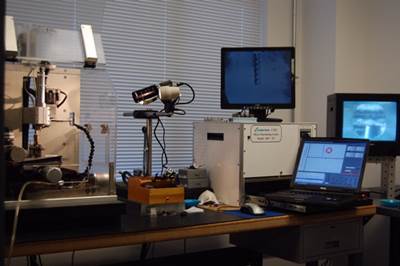

Read MoreVideo: Drilling 0.020-Inch Holes In Stainless Steel Aerospace Part

This footage on a small drilling machining also includes machining with full-size tools in the same cycle.

WatchWhat Is The Most Productive End Mill In Titanium?

Boeing experts recently responded to this question when it was submitted through our Aerospace Machining Zone

Read MoreWhere Does Diamond Make Sense In Machining Titanium?

Boeing machining experts say one application is drilling Ti-Composite stacks. PCD does well here. The group recently addressed this question submitted through our Aerospace Machining Zone.

Read MoreHow Do You Maximize Tool Life In Aluminum?

Boeing experts say climb vs. conventional is not the key. They recently answered a question submitted through our Aerospace Machining Zone, saying the key to tool life is actually chatter control.

Read MoreMachine-Ready Blanks

According to the company, its machine-ready blanks reduce overall part costs. They can be loaded directly into the machine without prep operations, which include sawing, grinding, flattening or squaring. Additionally, machine-ready blanks are said to require less time for adjusting setups and fixture offsets.

Read More

.jpg;maxWidth=300;quality=90)