Aerospace

Automated Honing Reduces Cycle Time by 75 Percent

Faced with increased demand for a critical aerospace part, this manufacturer sought to replace its manual honing machines with a CNC model. As a result, the company achieved a 300-percent increase in production, better ID surface finishes and dimensional tolerances, and the ability to produce a wider range of part sizes.

Read MoreWhat's the Best Process for Machining a Precise Hole in Aluminum?

This small hole is actually large enough that any of three different processes might be used.

Read More5 Axis Volumetric Error Compensation for Large Machine Tools

System simultaneously corrects tool position in multiple axes to tighten machining accuracies on large machines that cut complex shapes.

Read MoreWhen Spindle Speed is a Constraint

Though it won’t replace high speed machining, Boeing sees “low speed machining” as a viable supplement to higher-rpm machines. Using new tools and techniques, a shop’s lower-rpm machining centers can realize much more of their potential productivity in milling aluminum aircraft parts.

Read MoreVideo: Plunge Roughing in Aluminum

Even in aluminum, plunge roughing can be an effective way to realize high productivity.

WatchVideo: High Feed Milling in Aluminum

Footage shows roughing at 48 cubic inch per minute on a standard-speed machining center.

WatchPinch Milling from Top to Bottom

A multitasking (turnmill) machine that can mill a workpiece top and bottom at the same time has advantages for long, slender workpieces such as turbine blades, propellers and aerospace structural components. Includes video.

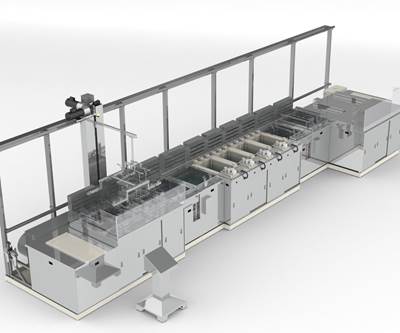

Read MorePassivation of Stainless Steel Parts: The Recipe for Success

Passivation—the process for making stainless steel parts more corrosion-resistant—is affected by how well the part is cleaned. It’s also affected by the choice of acid. Nitric or citric?

Read MoreMore Efficient Turbine Blade Milling

Video shows a multitasking machine milling a turbine blade in a cycle that few machining centers could replicate.

WatchVideo: High Speed Milling—900 ipm

Demonstation illustrates the kind of metal removal rate that is possible in aluminum at dynamically stable speeds.

Watch