Straight to Sand

Through direct CNC machining of molds and cores, this supplier of cast and machined parts skips the pattern-making step that would otherwise be fundamental to casting. The result is weeks of lead-time savings for complex parts that are needed in a hurry.

Share

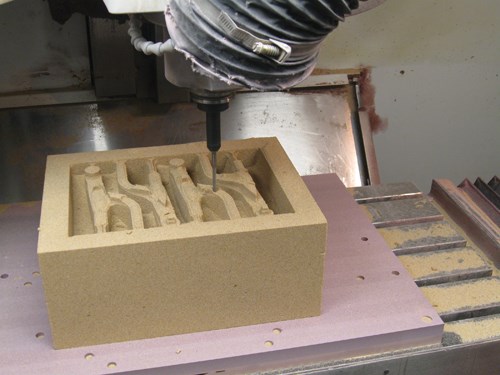

Here is video of the sand machining involved in the Toolingless process.

CNC machining is a proven technology for holding tight tolerances.

Reg Gustafson of Clinkenbeard knows this. Clinkenbeard is a supplier of short-lead-time castings in Rockford, Illinois. Mr. Gustafson says the company’s recognition of the basic effectiveness of machining ultimately showed it the way to respond, back when additive technologies for making molds and cores first began to succeed.

Additive processes eliminate the need for patterns to make sand molds and cores. They also eliminate the need for core boxes, rigging, gating and other foundry tooling.

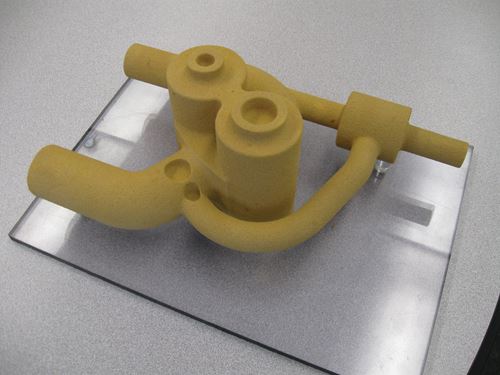

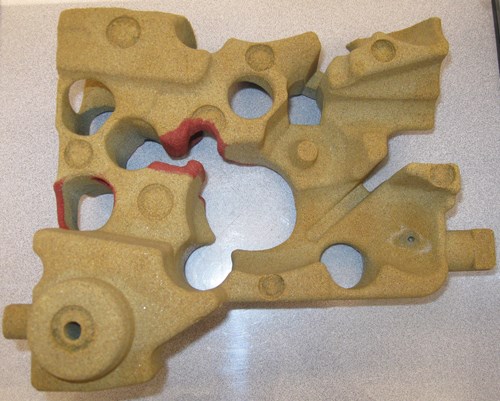

To compete, Clinkenbeard developed its own rapid process for doing away with patterns and other tooling. However, this process isn’t additive, it’s subtractive. The company’s patented process called “Toolingless” casting involves making foundry molds and cores on CNC machining centers. In developing this process, Clinkenbeard discovered just how productive CNC machining can be for quickly generating complex forms in sand.

Prototype Production

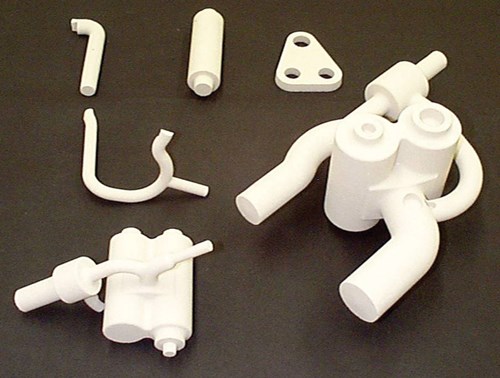

Even when patterns are used, though, Clinkenbeard is fast at casting. The company does not do long production runs, but instead specializes in short runs where the critical factor is time. Typical customers use Clinkenbeard to quickly obtain cast and machined prototypes so that their new products can be tested in the field. Clinkenbeard also provides “bridge manufacturing” services, making short production runs as needed until the customer’s own full-scale production comes online.

A typical lead time to obtain a complex new part that must be cast and machined is 4 to 6 weeks, Mr. Gustafson says. The Toolingless process, by eliminating all the work associated with the patterns, cuts that lead time in half. The process otherwise replicates conventional casting. Mold and core components are machined out of solid blocks of sand and binder, the composition of which is tailored to match whatever mixtures will be used in the production foundry.

There are some inherent difficulties with the process, Mr. Gustafson says. Unlike a metal chip, sand falls straight down. Thus, when sand is the “chip,” there is no practical method for clearing it out of the way of the cutting tool. A somewhat impractical method is used instead. The operator watches the process and follows the milling tool with a shop vacuum.

The sand also affects the machine. On the machining centers that are dedicated to this process, ballscrews get replaced every 2 to 3 years.

A final consideration is the quality of the sand itself. Virgin sand is needed. Typical foundry work reuses sand that has been reclaimed from previous castings. In these applications, soft spots or metal inclusions in the molds and cores are no problem, because the integrity of the tooling surface is all that matters. In the Toolingless process, though, these inconsistencies could compromise the life of the cutting tool—which, in turn, might compromise a long milling cycle.

Keep What Is Qualified

The payoff is a process well-suited to urgent lead times. It’s also excellent for jobs in which the part quantity is too low to amortize a pattern. Mr. Gustafson says the company uses this process routinely to improve the economy of casting orders that consist of just one piece.

Another important application involves foundry tooling that already exists. Many manufacturers certify or qualify their tooling, so that the introduction of any new tooling would demand a time-consuming requalification step. In these cases, a design change can sometimes be implemented far more efficiently by simply bringing some of the existing tooling to the machining center for modification through CNC milling.

Getting to the point where this Toolingless process was mature wasn’t easy, Mr. Gustafson says. Finding the right tooling, holding strategies and tool paths for generating complex forms in sand required trial and error.

However, getting to this process was (in a way) obvious—once the company recognized that foundry sand is machinable. The patented process that achieves time and cost savings for the company and its customers was the result—at least in part—of the company recognizing that it was not yet realizing all of the benefit that it could from CNC machining.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=970;quality=90)