-

-

-

-

-

SPONSORED

Articles

Precision Hole Making At High Cpk

Many shops and plants are moving from manual honing machines to CNC honing machines, as well as to robotically automated cells capable of controlling holes size to accuracies of 0.25µm (0.00001 inch). The inherent accuracy and process stability of honing have promoted this changeover because precision parts produced today must meet high Cpk requirements.Honing can produce a specified finish and a desirable crosshatch pattern on the bore surface, which helps retain a lubricating film for sliding components. Makers of outdoor power equipment, motorcycles, ATVs, hydraulics, pneumatics, gears, and valves are some of the users who have "discovered" automated honing in their drive to make parts with tolerances as tight as ±0.0002 inch (±5 µm) at high Cpk levels.

Read MoreThe Returns On Automation

Machine tool automation, particularly grinding machine automation, offers various returns on investment. Different shops notice different advantages, and sometimes shops overlook important benefits when they are deciding whether to automate.

Read MoreApplying Magnetism To Smooth Cutting Tools On A Grinding Machine

An alternate surface finishing device available on a tool grinding machine uses magnetism to swirl abrasive powder across the surface of a cutting tool. This creates a smooth surface finish and precisely rounded cutting edges.

Read MoreAnother Step Toward CAM Automation

A CAD/CAM software provider has taken an important step that will enable CNC machine tool users to benefit from emerging data-communications standards designed to promote a truly “paperless” manufacturing environment. The key is a STEP AP224 interface.

Read MoreGet Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

Read MoreMultitasking With A Small Footprint

The Integrex i-150 shows how a multitasking machine for small precision parts can combine done-in-one process with a compact structure to reduce floor space requirements. Most multitasking machines for parts of this size use a second spindle for endworking of parts after cutoff. This machine uses a swing-away workholding device instead.

Read MoreSmoothing Insert Surfaces Extends Tool Life

A post-coating finishing process smoothes any cracks in the outer coating of a cutting tool insert that develop during CVD and also removes droplets that PVD might leave behind. The resulting reduction in friction, heat and surface stresses is said to extend tool life and cutting performance.

Read MoreLarge Wire EDM Unit Gives Shop Room to Grow

This wire EDM job shop in Wisconsin acquired a submerged cutting wire machine that lets it handle larger, taller workpieces than just about any other job shop in the country. The new machine has a “column-up” option that adds a riser block between the X-axis saddle and the Z-axis column casting to give it exceptionally tall cutting capacity. The machine was installed in November 2007.

Read MoreAn Alternate Route For Generating An Alternate Tool Path

A universal toolpath engine for roughing pockets optimizes cycle times by maintaining a constant material removal rate regardless of part geometry. This toolpath engine is not a CAM system. Instead, users pay a monthly fee to upload geometries to a secure Internet server and quickly receive tool paths that can be used with any CAM system.

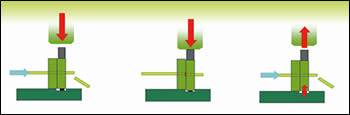

Read MoreCreating Workpiece Blanks Via Adiabatic Cutoff

Adiabatic cutting is an alternative cutoff process for high-production machining applications. It uses kinetic energy to create a shockwave of sorts that softens a narrow, vertical plane through barstock material. The energy is converted into heat faster than the material being cut can dissipate it, and this controlled plastic deformation separates the material.

Read MoreIt Begins With Belief

This shop’s approach to unattended machining focuses on the big picture.

Read MoreContinuous Turning On Turn-Mills

A new CAM feature continuously manages B-axis head rotation to allow turn-mills to completely turn inner and outer workpiece profiles using a single tool.

Read More