Meltio Wire-Laser System Reduces Material Waste

The Meltio M600 can seamlessly integrate into machine shops and production environments, enabling not only the printing of entire metal parts but also the addition of features to existing components and the repair of damaged surfaces.

Share

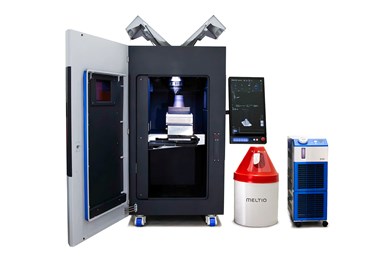

Meltio’s M600 metal 3D printer features blue lasers, a large build volume and a fully inert chamber for the best material properties. The printer is designed to solve the problems of long lead times, costly stock-keeping and fragile supply chains.

This wire-laser metal directed energy deposition (DED) system was conceived to introduce metal additive manufacturing (AM) to the world of industrial production outside of niche areas. The system increases productivity and reduces manufacturing costs, utilizes new materials and is ready to perform 24/7 with minimal operator interaction for autonomous production.

The combination of wire deposition, blue lasers, a large fully inert workspace (300 × 400 × 600 mm - X, Y, Z) and smart sensors enable the Meltio M600 to process demanding materials — from titanium to copper and aluminium alloys, and many more, including stainless steels, tool steels, nickel, invar and Inconel.

The system can also seamlessly integrate into machine shops and production environments, enabling not only the printing of entire metal parts but also the addition of features to existing components and the repair of damaged surfaces. This is facilitated by the built-in three-axis touch probe and support for various workholding solutions, including zero-point clamping.

Meltio says that manufacturing faces many challenges globally — from long lead times and stock-keeping costs caused by long and fragile supply chains to an ever-growing pressure to lower costs and reduce emissions.

The system uses welding wire as its feedstock, compared to the more common powder-based 3D printer. Having a wire material that is cheaper, safe to handle and does not risk contamination of users’ CNC machines can be an advantage for industrial integration, the company says. Printing parts with the wire-laser deposition process also produces high-quality components with material properties that are comparable to conventionally manufactured parts.

The company’s blue laser deposition head increases printing speed while reducing energy consumption because of the increased absorption of the short wavelength light — compared to most industrial lasers which emit near-infrared light.

Related Content

-

Digitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

-

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

.jpg;maxWidth=300;quality=90)