NASA Brings Technology to New Heights

Meet NASA mission system engineer Mike Menzel and learn more about the James Webb Space Telescope at Mitsui Seiki USA’s booth (338700) in the South Hall from 11:00 a.m. to 11:45 a.m. on Thursday, September 15.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

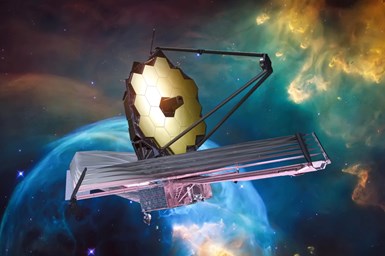

The James Webb Space Telescope’s mirrors were machined on Mitsui Seiki horizontal machining centers. Photo Credit: Mitsui Seiki USA

Mike Menzel, NASA mission systems engineer for the James Webb Space Telescope at the Goddard Flight Center in Greenbelt, Maryland, will speak at IMTS 2022 at Mitsui Seiki USA’s booth (338700) in the South Hall from 11:00 a.m. to 11:45 a.m. on Thursday, September 15. He will share images and anecdotes about the challenges he and his team of engineers experienced creating the largest and most complex space science observatory ever built.

A close-up photo of the hexagonal beryllium mirrors Mitsui Seiki machined for the James Webb Telescope, the largest optical telescope in space.

The James Webb Space Telescope (JWST) has a colossal mission — to find the first galaxies that formed in the early universe, and spot stars forming new planetary systems. After 24 years, the JWST successfully launched in spring 2022, and transmits awe-inspiring images to us almost daily.

Menzel will share what NASA has learned so far from the JWST, along with its flight milestones, its unique observatory design and engineering (including the specially-made horizontal machining centers produced by Mitsui Seiki, which were used to make the JWST’s mirrors), and facts about both the scientific discoveries being made with it and the science behind it.

Related Content

-

Murata Machinery Single-Spindle Turning Center Maximizes Productivity

IMTS 2024: Murata Machinery USA announces the MSR60 single-spindle CNC turning center with multitasking capabilities and built-in gantry loader automation.

-

SMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

-

Tsugami Lathe, Vertical Machining Center Boost Machining Efficiency

IMTS 2024: Tsugami America showcases a multifunction sliding headstock lathe with a B-axis tool spindle, as well as a universal vertical machining center for rapid facing, drilling and tapping.

.jpg;maxWidth=300;quality=90)