-

-

-

-

-

SPONSORED

Articles

Macro Economics

Instead of NC programs that are dedicated to particular parts and machines, this plant now uses macro programs that react to geometric variations across broad part families. The plant wrote these macros itself, and the return on this investment has been dramatically greater productivity.

Read MoreWhere Is Your Wiggle Room?

"Lights out" doesn’t require an intense commitment. This job shop achieves flexible unattended machining when it needs it using palletized HMCs.

Read MoreFive-Axis Machining Has Special Workholding Needs

This clamping system allows a workpiece to be rigidly clamped while raised up from the surface of the worktable on a five-axis machining center. Moving the workpiece away from the table creates clearance for the spindle nose and cutting tool when the table swivels the workpiece for multi-sided machining, or when the spindle head rotates and swivels to do contouring or sculptured surfaces. Without this clearance, the user may be forced to refixture the part or to switch to a longer, less rigid tool.

WatchRAMTIC System Still Ticking

When it first appeared in the early 1990s, RAMTIC (Renishaw’s Automated Milling, Turning and Inspection Center) pioneered the use of portable carrousels for palletized workpieces and the use of artifacts, or master components, by which a machine tool could check its own dimensional calibration. This innovative approach to process control is still highly effective as applied in the company’s most advanced machine shop, which opened in 2006. Carrousels and artifacts are very much a part of this new shop’s remarkable success.

Read MoreMachine Tools Used As Dedicated Equipment…For A Little While

Two keys to this shop’s success are versatility and speed. It uses flexible machining centers, rather than dedicated equipment, and constantly reconfigures them into new cells for new jobs. The speed at which it can do this, in addition to in-house tombstone manufacturing capability, provides the nimbleness to quickly respond to its customers’ needs.

Read MoreWhen Four Spindles Make Sense

For the right applications, four-spindle CNC chuckers offer practically zero delay for part loading. That’s because two spindles can be loaded while the other two are making chips.

Read MoreHigh Speed Machining Without The Fast Spindle

Relying on axial chip thinning lets a larger-diameter tool realize some of the benefits of high speed machining even if the machine's spindle speed is low.

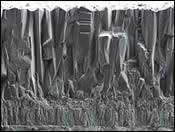

Read MoreAtomic-Level Engineering For Greater Tool Life

Manipulating the direction of aluminum oxide crystals produces a cutting tool coating that is harder, and also cuts cooler.

Read MoreHow CNC Led To Cells

Bringing CNC into a previously manual process set this shop on a lean path that has led to continuous flow production.

Read MoreDouble-Sided Productivity

Having a bar feeder on one side and a parts carrousel on the other side ensures that a turn-mill machine will achieve maximum productivity, whether the workpieces are mostly milled or mostly turned. In general, smaller parts are machined from bar stock, even if only milling operations are involved. Larger parts are loaded an unloaded by a transfer device fed by the carrousel.

Read MoreBecoming More Than The Mom & Pop Race Shop

Carney Custom Machining started with a VMC and customer base largely comprised of drag racers. Now the shop is vying to win work from other sources, and CNC turning is a big part of that strategy.

Read MoreA Machine Tool Show In Moscow

The market for metalworking equipment in Russia is enticing but complex.

Read More