Applying Magnetism To Smooth Cutting Tools On A Grinding Machine

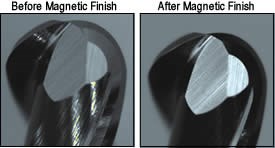

An alternate surface finishing device available on a tool grinding machine uses magnetism to swirl abrasive powder across the surface of a cutting tool. This creates a smooth surface finish and precisely rounded cutting edges.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreCutting tool manufacturers often perform post-grinding operations such as honing and polishing to improve tool surface finish and generate precisely rounded cutting edges. These operations lead to better chip flow, longer tool life and improved adhesion prior to coating processes. They also reduce the coefficient of friction of coated tools by removing droplets and other imperfections left behind after CVD or PVD.

Schütte TGM offers an alternate surface finishing method on its WU-305 tool grinding machines. The process uses magnetism to swirl abrasive powder across the surface of a cutting tool to smooth and improve its finish. The technology was originally designed for use on stand-alone equipment, but a magnetic finishing module has been engineered to be compatible with the wheel-changing mechanism used on the WU-305 machines. This enables the machines to both grind cutting tools and to treat them via magnetic finishing in one setup.

The primary components of the finishing module are two revolving magnetic discs located on either side of an enclosure containing the abrasive powder. Each powder grain contains both abrasive and magnetic material. Once a tool is inserted into the enclosure, magnetism causes the powder to swirl around the tool and smooth its surface. This magnetic finishing technology is also being applied in aerospace and automotive applications to reduce friction between mating components such as gears and engine parts.

Schütte currently offers four powder grit sizes—400, 600, 1,000 and 1,500—which users choose based on their finish requirements. The company says the magnetic finishing process can deliver 0.02-µm Ra and 0.08-µm Rz. In addition, it is said to generate a reproducible radius of cutting tool outside edges and chipping edges between 3 µm and 50 µm.

The WU-305 machines can grind, mill, belt-sand and polish, so their coolant system has been designed to accommodate machining chips, grinding swarf and the powder used in the magnetic finishing operation.

Related Content

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)