How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Share

Reader Question:

We are buying our first five-axis machine and it arrives soon. We are very excited about the benefits we know it will bring, but recognize it will require some changes in the shop to make the most of it. Can you guide us on where we might look to be as successful as possible?

Miller’s Answer:

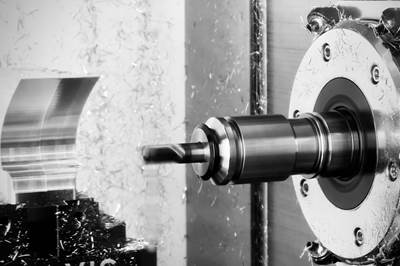

The holy grail of machining is always a “done-in-one” setup, which is why Swiss machines, twin-spindle lathes and multitasking machines are so productive. In the milling world specifically, five-axis is the answer to this. There have been major improvements in the availability of these machines, and the accessibility through CAM, so that most shops have five-axis as part of their growth strategy.

While there are many changes to adopt when moving to five-axis, they are all simple adaptations to make, and they all compliment the overall goal of better parts through less operations. The biggest change from three-axis to five-axis is the workholding needed to allow access and clearance. From there, some adaptations with toolholders, fresh speeds and feeds, as well as understanding the controller/CAM side, will have your shop on track.

While vises and soft jaws work just as well on a five-axis as they do on a three-axis, they are not a great complement to the goal of “done in one” with your new machine. Therefore, the first place to look for success is taking your existing parts and adapting them to workholding that allows for more part access, while maintaining a suitably rigid clamping. The industry has answered this problem with a litany of dovetail clamping solutions, small self-centering vises and fixture pyramids, which fill the work zone for maximum in-cut time.

With that being said, one downside to five-axis workholding is that it often requires a standoff of some type to create distance between the part and the machine table. This enables spindle clearance when working on the positive and negative sides of the tilt axis. While necessary, this standoff consumes the work zone, and also creates a less-rigid scenario overall, so a lot of care needs to be taken when laying out your new work and determining what fits and what doesn’t. You may be surprised that the total usable work zone is much smaller than advertised.

As the workholding drives the machine setup in a particular direction with dovetails, pyramids and standoffs, the toolholders used on a five-axis machine must also compliment the goal of a done-in-one setup. This means toolholders that are generally longer — sometimes much longer — than what you may use on a three-axis vertical machining center (VMC) to reach parts that are in the center of a large five-axis table. With these longer toolholders, more care is required to check runout and balance, and to not hinder the inherent accuracy of the single-operation process. Modular toolholders and slim setups will become the norm here, and you should expect to invest significant money here, which will pay off in quality improvements.

Even if you could keep the same toolholders and workholding as the previous three-axis processes, you should expect very different cutting performance than what you may be used to, due to the change in machine structure. A standard VMC features a feedback loop from cutting tool to table that is very compact, especially with short tooling. On a five-axis machine, there are two new degrees of mechanical freedom that exist between the spindle and table.

This drastic change in structure, combined with less rigid workholding and tool setups, means the go-to speeds, feeds and depths of cut you were accustomed to (and maybe even had templates for in your CAM system) will no longer be valid. It doesn’t mean something is wrong with your machine or tools, it just means the new five-axis machine may need some more careful consideration during roughing. Be flexible here, because adding some time to roughing does not negate the benefits of a “done-in-one” setup, nor the broader efficiency gains of the five-axis machine. The focus should be on overall productivity, not specifically metal removal rate.

Three functions that you will want to get familiar with on your new machine and are ubiquitous with all five-axis machining are dynamic fixture offset (DFO), tilted working plane (TWP) and tool center point control (TCP). The names may change depending on your specific machine controller, but these are the more typical industry terms, and the functions are broadly the same. If your shop was already doing fourth-axis work, you may already be familiar with DFO, but TWP (allowing for work on complex compound planes) and TCP (allowing complex tool motion and vectoring of the tool) will be known to you. While it would take another month’s column to detail these further, please understand these will become common vocabulary with your new machine.

With the new functions you need to learn, your CAM system will need a big upgrade to utilize the machine fully. For example, your current CAM package may only support 3+2 machining, but not complex, full five-axis motion. Five-ax-is motion often requires more effort to program to get the exact motion you want, so further training is highly recommended. Lastly, you should expect to spend time debugging your new postprocessor for your applications.

Above all of the tangible things you need to buy for this machine, the most overlooked is training. Most new machines of this type will come with on-site training of some kind, but this just scratches the surface and is usually focused on the operator. While it is always difficult for a busy shop to pause for anything, you must commit sufficient time to this process. You must also be diligent to get all parties (programmer, setup personnel and operator) involved with this new asset. It’s sad to say, but I can’t tell you how many shops I’ve seen with a newly installed machine sitting idle because they weren’t trained enough and stick with what is more comfortable. By committing to the learning process, the team will be more confident much faster, the machine will contribute to the overall shop workflow much earlier and the ROI will be realized much sooner.

Do you have a machining question? Ask the expert. John Miller leans on more than a decade of industry experience to answer machining questions from MMS readers. Submit your question online at mmsonline.com/MillersEdge.

Related Content

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

Tips for Mastering Stainless Steel Machining

When getting a grip on stainless steel, make sure you are very specific in how you talk about it and understand the pertinent information you need.

Read MoreHow Important is Spindle Power?

Consider these spindle attributes to make a choice that is balanced, usable and compliments your processes as best as possible.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More