Smoothing Insert Surfaces Extends Tool Life

A post-coating finishing process smoothes any cracks in the outer coating of a cutting tool insert that develop during CVD and also removes droplets that PVD might leave behind. The resulting reduction in friction, heat and surface stresses is said to extend tool life and cutting performance.

Share

Autodesk, Inc.

Featured Content

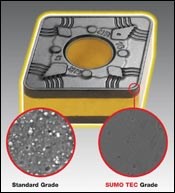

View MoreCoatings are typically applied on cutting tool inserts using chemical vapor deposition (CVD) or physical vapor deposition (PVD). In either case, imperfections in the coating’s outer layer can occur as a result of coating application, according to Iscar (Arlington, Texas). High heat followed by cooling during CVD can leave behind micro-sized cracks in the coating. Although PVD does not involve high heat like CVD, the PVD process can leave behind tiny droplets of coating material on an insert’s surface. These ragged surface imperfections adversely affect chip flow and insert life.

Such issues led Iscar to develop a proprietary, post-coating finishing process to improve insert surface quality. The company’s Sumo Tec finishing process smoothes any cracks in the outer TiN coating that develop during CVD and also removes droplets that PVD might leave behind. The resulting reduction in friction, heat and surface stresses is said to extend tool life and cutting performance. In addition, the process improves insert toughness and chipping resistance to reduce the chance of a built-up edge condition, the company says.

An example of the droplets inherent with the PVD coating process can be seen in the left-hand, close-up shot on this page. The right-hand image shows how the droplets have been removed via the Sumo Tec finishing process. The portions of the insert that received the finishing process are black in color.

In addition to the finishing process, Sumo Tec insert technology features a new series of tungsten carbide grades. It is used with new versions of Iscar milling, turning, drilling and parting/grooving tools. For example, the Sumomill T290 end mill family provides a number of cutting edges on a small tool diameter to enable increased feed rates and high metal removal rates. The tangentially helical inserts are clamped on the periphery of the tool body. The resulting large tool body core is said to provide high torsion resistance.

The expanded Heliturn LD family of turning tools uses helical inserts designed with highly positive, radial cutting edges and positive rake angles. This combination results in reduced cutting forces. A new lever-clamping tool design facilitates chip flow, particularly when performing longitudinal turning, undercutting and round profiling.

Iscar’s Sumodrill line uses adjustable, replaceable cartridges to perform rough drilling operations ranging in diameter from 61 mm to 80 mm. Spacers of varying thicknesses can be used to bring the interchangeable tool cartridges to the required diameter.

The Tang-Grip line of parting tools also has a tangential insert design. The single-ended insert can perform parting, grooving and interrupted grooving operations. Tang-Grip tools have a tangentially oriented insert pocket to allow parting at high feed rates. The tool have no upper clamp to improve chip flow and reduced the likelihood that streaming chips will damage the tool body. These tools have been designed so that the insert won’t pull away from the tool body during retraction.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.