CAD/CAM Software for Machining

CAD/CAM Software is used to generate part designs and CNC machining programs corresponding to part designs. Short for “computer-aided design/computer-aided manufacturing,” these systems create these programs for CNC machine tools. In general, CAM development has proceeded along two different tracks. Geometry-based CAM systems used in die/mold machining and other applications focus on complex milled geometries. Algorithms provide specific and efficient ways for machining complex geometries with both high precision and long tool life. By contrast, feature-based CAM systems are generally used in the production machining of geometrically simpler components.

ESSENTIAL READING

VIEW ALLWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreSimulation Saves Money When Machining Expensive Parts

Jobs machining expensive materials mean Keselowski Advanced Manufacturing needs to be extremely cautious. The operations manager says Vericut not only prevents mistakes, it shortens cycle times.

Read MoreMastercam Offers Free CAD/CAM Courses to Take From Home

The free Mastercam University courses are available through Dec. 31, 2021.

Read More4 Things to Incorporate in CAM-System-Generated CNC Programs

Streamline G-code programs created by CAM systems.

Read More7 Tips for Programming Ceramic Cutting Tools

Ceramic tools require different thinking and a willingness to tweak tool paths developed with carbide in mind.

Read MoreCAM Simulation Gets Toolmaker up to Speed with B-Axis EDM

Software simulation helped this machine shop learn how to program its new advanced, high-tolerance wire EDM. The software also helped the shop turn job quotes around quickly.

Read MoreLatest CAD/CAM News And Updates

Phillips Precision CAD Library Features Fixturing Component Designs

Phillips Precision Inc. has released a library of CAD models for its lineup of Inspection Arsenal fixturing components.

WatchModuleWorks, Toolpath Sign Technology Partnership for Accelerated Software Performance

ModuleWorks and Toolpath announce a technology partnership that intends to utilize intelligent cloud-based manufacturing solutions for machining estimation and CAM automation.

Read MoreVerisurf Software Features Optimized Metrology Workflows

Verisurf 2025 includes optimized workflows for inspection, reporting, reverse engineering, tool building and guided assembly.

Read MoreFaster Programming and Training Helps Automotive Shop Thrive

Features that save on training, programming and cycle times have enabled Speedway Motors to rapidly grow and mature its manufacturing arm.

Read MoreConcepts NREC Updates Five-Axis CAM Software Efficiencies

IMTS 2024: Concepts NREC showcases updates to its Max-PAC five-axis CAM software, which aims to simplify and accelerate geometry setup, the editing of blade points and the rate of collision avoidance options.

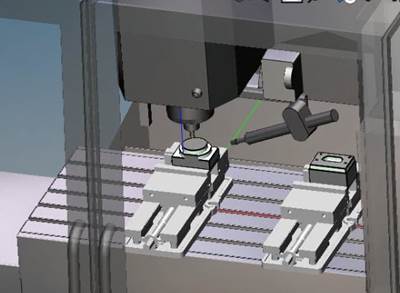

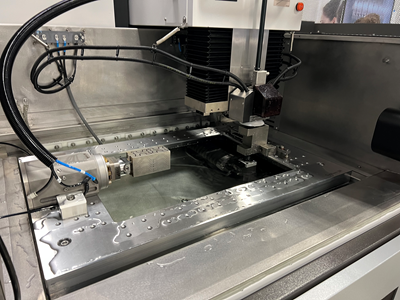

Read MoreHCL CAMWorks Software Features Digital Twin of Machine

IMTS 2024: Machine Aware Programming enables CNC programmers to identify potential issues earlier in the programming process, increasing productivity and improving part quality.

Read MoreFeatured Posts

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreThe Intersection of Work, Play, Technology and Independence

The February issue dives into digital technologies that not only streamline production, but make a tangible difference in people’s lives.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreHybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Read MoreFAQ: CAD/CAM

What is CAD/CAM?

In the world of metalworking, the CAM part of CAD/CAM (computer-aided design/computer-aided manufacturing) generally means software for programming CNC machine tools. CAD is the computer-aided process that creates a design of a part or object.

Source: CAM at a Crossroads

What is CAD/CAM programming?

There are three methods of writing CNC programs, including using CAD/CAM software. CAD/CAM programming minimizes the need for the programmer to perform complex math calculations. Due to the minimal amount of math required by the programmer, CAD/CAM programming tends to be more efficient than manual programming.

By using an existing CAD drawing file and importing data into the CAM software, the programmer only needs to decide on which process and tooling to employ, typically using a list of tooling data and cutting conditions. The CAM software then calculates all of the moves necessary to machine the part.

What are the disadvantages of using CAD/CAM?

Programmers must keep in mind that there is some potential for unintentionally entering incorrect data. Another problem is that sometimes, the original drawing file is not available to the CNC programmer.

What is the relationship between CAD and CAM?

Most product design is performed on computers using CAD software. Then, that design or drawing file data is imported into the CAM software. After a few selections from the programmer, the CAM software will use that data and calculate the necessary moves to machine the part.

What are the advantages of CAD/CAM?

CAD/CAM programming minimizes the need for the programmer to perform complex math calculations. Due to the minimal amount of math required by the programmer, CAD/CAM programming tends to be more efficient than manual programming.

.jpg;maxWidth=300;quality=90)