Simulation Saves Money When Machining Expensive Parts

Jobs machining expensive materials mean Keselowski Advanced Manufacturing needs to be extremely cautious. The operations manager says Vericut not only prevents mistakes, it shortens cycle times.

Share

KAM specializes in 3D printed metal parts, both in the printing and the finish-machining stages. These parts are worth tens of thousands of dollars by the time they reach the machines, and thus require careful strategies for machining. Photo Credit: Keselowski Advanced Manufacturing

Since 2018, Keselowski Advanced Manufacturing (KAM) has become a preferred supplier to companies throughout the aerospace and defense, energy, space, automotive and performance motorsports industries.

Representing a new breed of vertically integrated hybrid manufacturing firms, KAM specializes in the design and production of 3D-printed metal parts that are then finish-machined on a fleet of high-end CNC machine tools. It's demanding, difficult work that is compounded by the fact that any mistake can undo weeks of laser bed fusion manufacturing and cost tens of thousands of dollars in material and machine time.

"Unlike machining from billet and bar stock, the parts we're cutting already have considerable value to them,” says James O’Toole, KAM’s operations manager. “Scrap at this point in the manufacturing process could cause serious problems for our customers, never mind the internal expense.”

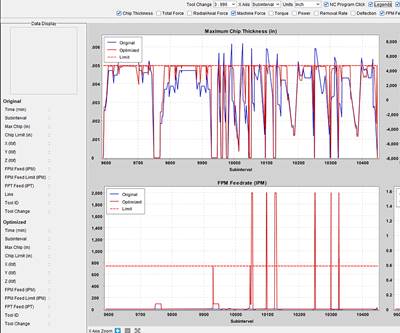

Simulation provides a way to avoid this expense — but time spent simulating production needs to be recouped elsewhere for efficient cycle times, so KAM also needed software that could perform effective toolpath optimization. According to O’Toole, Vericut from CGTech struck the right balance for KAM.

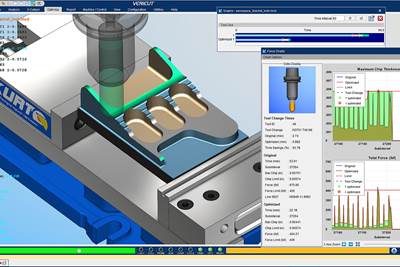

“Not only does Vericut help us to ensure that the first part is a good part, but it helps us to reduce our setup times, eliminate broken tools and prevent crashes,” O’Toole says.

The Right Software for the Right Job

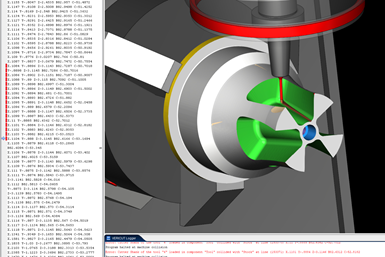

KAM’s shop floor is home to a variety of Mazak equipment, among them an HCN-5000 horizontal machining center; a Variaxis i-800 five-axis, twin-pallet vertical machining center; a Quick Turn 350MSY turn-mill center; and several Integrex i-300S seven-axis multitasking lathes. The additive side of KAM’s production area also boasts a large array of equipment, with nearly two dozen laser powder bed fusion (LBPF) printers from EOS, SLM Solutions and GE Concept Laser. Some have dual- or quad-laser capabilities, and all are capable of building parts from aluminum, Inconel 625 and 718, titanium Ti64, Haynes 282 superalloy and several other aerospace-grade metals.

Under O’Toole’s supervision, the two departments work very closely with one another and KAM’s design and engineering department. The process plan for any part starts by creating the 3D printing job or “build” in Materialise Magics software, simulating it in Netfabb Ultimate and then releasing it for 3D printing. After thermal processing, the printed job moves to the machining area. It’s here that KAM uses Vericut to simulate the NX-generated part program, checking for gouges, uncut material and collisions.

"We have a very strong programming team, but we're all human, and humans make occasional mistakes," O'Toole says. "While it doesn't happen very often, we've had multiple instances where Vericut has caught errors that would have scrapped a very expensive workpiece.”

Collisions are disastrous for KAM, so Vericut’s focus on collision avoidance made it especially attractive for the shop. Photo Credit: Keselowski Advanced Manufacturing

Wayfinding Workholding

O’Toole noted that one of the more important considerations when machining 3D-printed parts is workholding. Some parts are machined still attached to the build plate, making workholding much easier, but others need to be cut away beforehand. In these instances, determining the best way to fixture what are often thin-walled parts containing complex geometries and freeform surfaces can be quite challenging.

On a traditional billet-made part, operators can determine any subsequent locating features during the first operation, O’Toole says. With additive, the parts don't have those datums defined, even though there are features that must align to them when complete. He compares this to castings and forging, which require finding the “part within the part.”

“You need to strategically look at how you are aligning and then probing the part to make sure that the features you’re machining end up in the right place,” O’Toole says. “We use Vericut here as well, to simulate our probing macros. Not only does it help us to ensure that the first part is a good part, but it helps us to reduce our setup times, eliminate broke tools and prevent crashes.”

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Aerospace Shop Adopts NC Optimization as a Means of Continuous Improvement

Steelville Manufacturing adopted CGTech’s Vericut NC verification software to safeguard its high-volume/high-mix work, but found unexpected benefits from its Force Optimization module.

Read MoreMetal Additive Manufacturing: Multitasking’s Latest Trend

Why are an increasing number of machine tool builders adding additive manufacturing to their equipment’s already versatile machining capabilities? Because additive and subtractive are complementary.

Read MoreCGTech's OptiPath and Force Modules Prove Complementary

The OptiPath and Force modules of CGTech’s Vericut software have improved programming and cycle times at Ultra Machining Company.

Read More

.jpg;maxWidth=300;quality=90)