CAM Simulation Gets Toolmaker up to Speed with B-Axis EDM

Software simulation helped this machine shop learn how to program its new advanced, high-tolerance wire EDM. The software also helped the shop turn job quotes around quickly.

Share

Autodesk, Inc.

Featured Content

View More

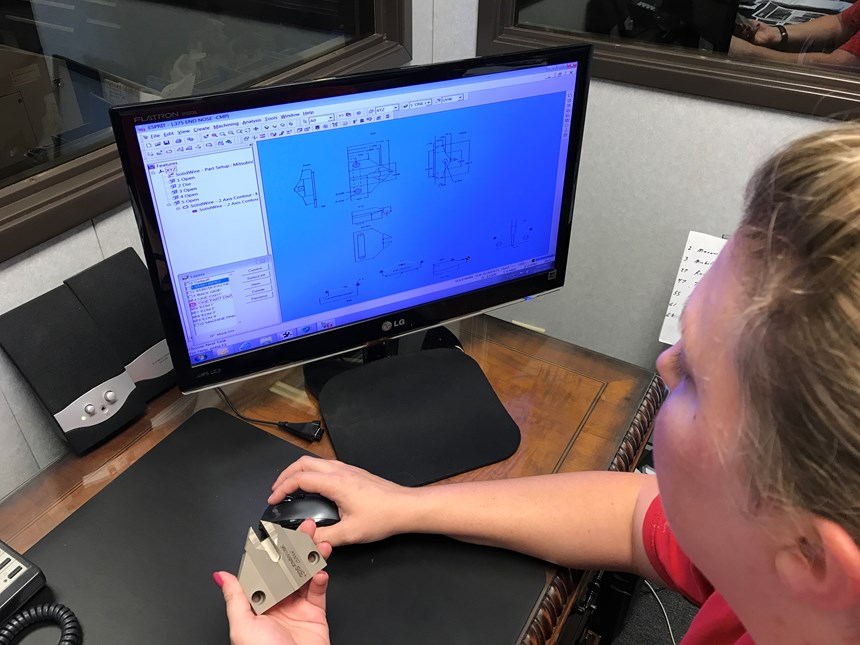

In choosing DP Technology’s Esprit CAM software to write programs for its CNC grinders and wire EDM, MCC Tooling found a CAM system so user friendly that the owner’s young grandchildren sometimes use it. More importantly, Esprit’s efficient programming saved MCC Tooling time and money getting up to speed with an advanced wire EDM and now positively impacts both machining and quoting.

MCC Tooling makes and resharpens custom cutting tools, step drills, form tools and dovetail cutters in quantities ranging from one to as many as 100 pieces for customers in the oil, airline and medical industries. Marcus Alexander founded MCC Tooling in 1984 in the Dallas suburb of Garland, Texas, with leased space and a single grinder. The company has since grown into a 10-person business with a variety of machines, including 17 grinders working with carbide, stainless steel and high speed steel parts.

MCC Tooling began using Esprit in 1999, when it purchased its first wire EDM, a Mitsubishi FX 10. “After hours of extensive research and vetting different programs and software, we felt Esprit would fit our needs and our price range perfectly,” Mr. Alexander says. “Esprit is user-friendly, works seamlessly with our machines, and it integrates well with SolidWorks. It’s so easy that my grandchildren have come here and programmed their own things for us to cut out for them.”

Virtual Trial and Error Yields Real Benefits

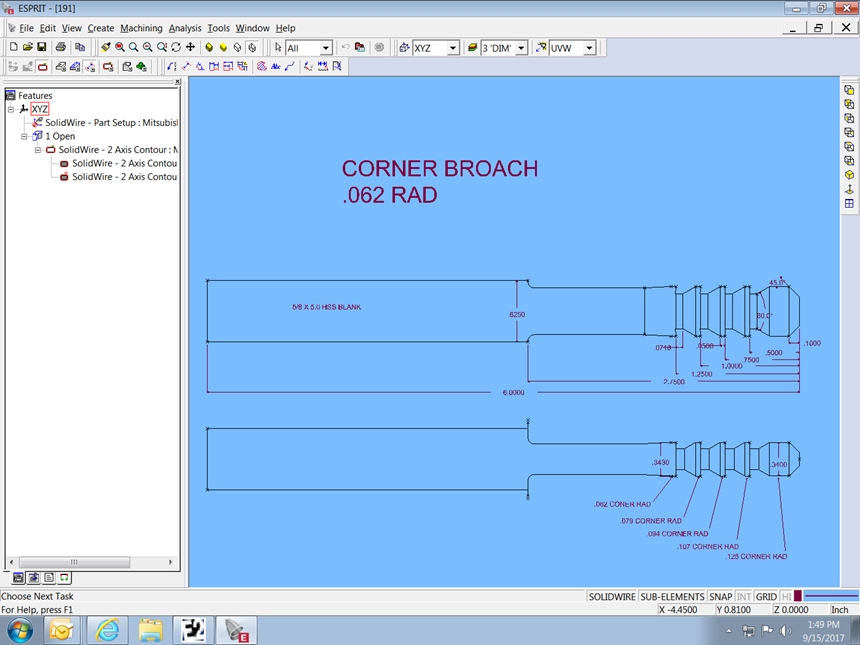

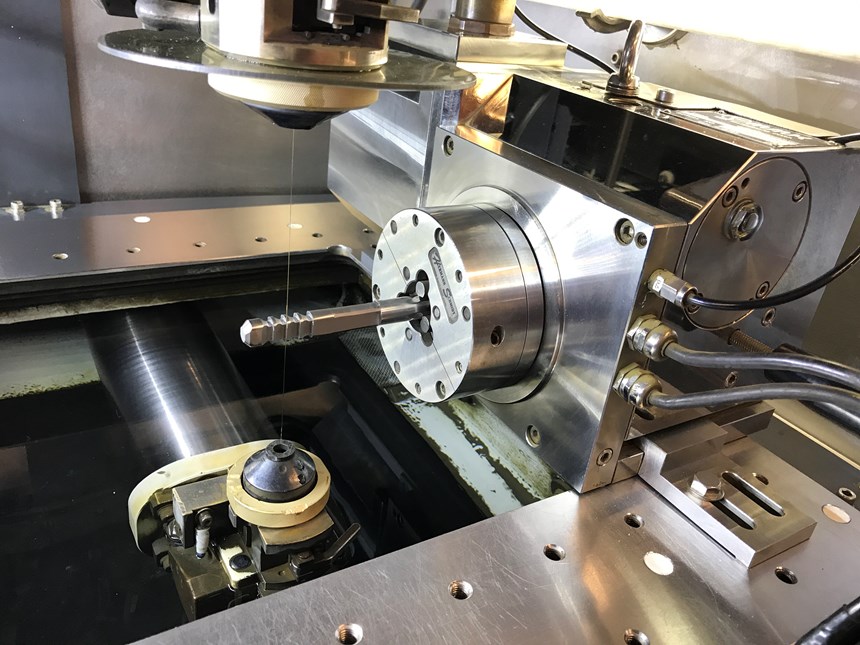

In 2013, Esprit helped the shop move to a Mitsubishi MV1200-R with B axis, which Mr. Alexander purchased because it could hold closer tolerances than the FX 10. While learning how to program it, MCC machinists initially resorted to trial and error. Esprit’s software simulation enabled them to take this exploratory approach without severe consequences. As Mr. Alexander tells it, a major benefit of the software was the ability to see the heads moving on the software’s simulation before running the part program on the EDM itself. This ability reduced the time wasted by running a potentially incorrect part and also avoided scrapping parts in the process. In the end, Esprit helped MCC get up to speed quickly with the machine. Now, it takes less than two minutes to set up the B-axis EDM.

The MMK Matsumoto B axis on the EDM made indexing from tooth to tooth far more accurate. The shop cuts a lot of multiple-flute form cutters, and before the MV1200-R, making these parts required several operations on different machines as well as a longer time to set up the FX 10 EDM. Now, using Esprit, MCC can program tools in only four additional steps. The process is also very repeatable: “We can mount the tool in the B-axis EDM and walk away knowing that we’ll get the perfect tool every time,” Mr. Alexander says. Esprit also enables operators to check all the clearance and rake angles on the tools to make sure they will function correctly and that all the dimensions are correct.

CAM Simulation’s Impact on Job Quoting

Esprit has also become a boon when it comes to job quoting. With more companies competing for projects, MCC must make sure that it provides precise job quotes quickly. “We have to know how long something will take to run in order to accurately quote a job, and we have to accurately quote a job so we don’t lose money or time while running the machine,” Mr. Alexander says. “With Esprit, after we program a job, we can produce the code and see exactly how long a job will take to run.” Mr. Alexander can draw up a print in minutes, send it to the customer and, if approved, have it running on the EDM the same day.

Occasionally, customers come in without prints or with a tool that is so badly worn that it is almost impossible to measure correctly. Once they have an inkling of how to proceed, Mr. Alexander and his team find it easy to draw up the tool in Esprit and figure out the other dimensions. Esprit also enables MCC to more easily double-check customer measurements.

MCC was recently commissioned to make a double-ended tooling insert for a customer, and Mr. Alexander was able to use Esprit to draw the insert to the customer’s exact specifications and turn it into EDM code within seconds. He then used Esprit to draw a fixture that would hold a carbide blank on a CNC grinder. The job was tricky: The fixture had to be made so that the blank would locate in exactly the same spot every time on the grinders. Mr. Alexander designed a second fixture to hold the insert while he cut the form on the EDM. The process was originally supposed to take four operations, but Mr. Alexander reduced it to two using a four-axis program. Best of all, this method resulted in the ability to machine the insert in the same manner every time—Mr. Alexander can simply insert a carbide blank and go. The customer, which had searched unsuccessfully for a machine shop that could make the insert properly, was so pleased with the outcome that it now orders around 50 tools per month from MCC Tooling.

These days, Mr. Alexander spends most of his time quoting jobs, so being able to cut down on programming and machining time with Esprit is beneficial, allowing him to spend more time completing other tasks around the shop. “Our industry is fast-paced and everyone needs a fast turnaround on jobs. Time is money for us.” And it’s clear that with Esprit, MCC Tooling is translating shorter quoting, programming and machining times into high value for its business.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)