Hybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Share

Automation often focuses on the movement of parts to keep machines cutting, but more and more systems are enabling manufacturers to automate tasks once thought too cerebral for a computer to handle. For GF Machining, this is taking the form of dynamic programming, which enables the company’s EDM controls to save and automatically generate toolpaths.

A Tale of Two CNCs

For years, GF Machining has provided two options for EDM controls: a G-code CNC and a control with an integrated CAM system and human-machine interface (HMI) that enables the user to reset priorities at the machine. While many users prefer the simplicity and familiarity of the G-code control, the CAM system enables the user to fluidly adapt to changes in parameters thanks to dynamic programming.

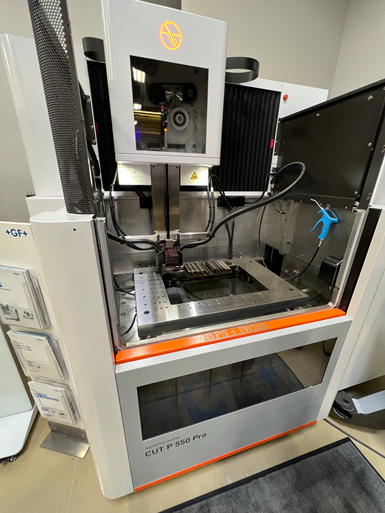

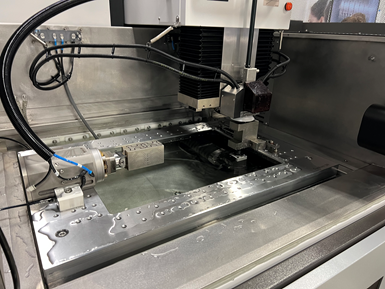

Dynamic programming enables the user to quickly change priorities in the middle of a job by generating the G-code to make the desired changes. GF Machining is making this feature available on its Uniqua control, which is available on many of the company’s machines, including this Cut P 550 Pro.

Dynamic programming enables the control to adjust priorities with minimal user input, autonomously producing G-code to fit the needs of the job. The control saves part programs and cutting paths in a database accessible at the machine, which enables users to make changes on the fly. “Say you programmed the machine to make the A cut, then B, then C,” explains Eric Ostini, GF’s head of business development for North America. “With dynamic programming, you can change it from A-B-C to A-C-B. Or if you need to suddenly prioritize a different workpiece, or if a wire is slightly out of position, you can make those changes immediately.”

This feature is excellent for operations that need close operator oversight. For example, users can alter how they enter or exit a part at the control. “Let’s say you start out wanting to cut the part straight-on,” Ostini says, “but a large burr forms where you would exit. You can quickly change the wire path to exit the part radially to avoid the burr.” The control uses algorithms to determine the specific movements necessary, enabling users to avoid the burr without having to program the G-code needed to do so.

While these capabilities are useful, many users still prefer the G-code control, especially for simpler jobs. “Sometimes you just need to make a couple slices, and you don’t want to navigate a menu for that when you can just plug in the G-code,” Ostini says. “As rewarding as it is, the CAM system can be difficult to learn.”

Hoping to bridge the gap between its G-code and CAM customer bases, GF developed the Uniqua control, which incorporates both the G-code and CAM systems in a single control.

The Uniqua control is an HMI that functions as a hybrid between GF Machining’s G-Code CNC and integrated CAM system, enabling the user to quickly switch between programming G-code and using the CAM. The company sees it as a way to encourage users to experiment with dynamic programming, which can dramatically reduce time spent programming parts and makes lights-out manufacturing more accessible.

Uniqua offers users the opportunity to quickly switch between a G-code CNC and a simplified version of the company’s CAM-integrated control. This enables users to benefit from both the simplicity of a G-code CNC and the adaptability of dynamic programming. “We see Uniqua as a way of providing customers with a familiar control while also making dynamic programming options more accessible to users who aren’t familiar with it in practice,” Ostini says.

Making these options more accessible matters because Ostini sees dynamic programming as an important step toward automating EDM for lights-out manufacturing.

Dynamic Programming and Unattended EDM

One of the clearest examples of the usefulness of dynamic programming is the Early/Late capability. “Let’s say on a Friday afternoon, an operator puts a workpiece on each side of the machine,” Ostini explains. “Together, they have twenty cavities to cut, but the operator’s shift ends in two hours — only time to cut one cavity.” Normally, an operator in this situation has two options: reprogram the entire job to run over the weekend unattended or do what they can in two hours and finish most of the work on Monday.

“With dynamic programming, the operator can switch to a late capability and walk out the door,” Ostini says. With the late capability, the control independently reorganizes the program to complete as much work without operator intervention as possible. Not only does it find an efficient way to make as many cuts as possible, it recognizes which steps require the operator’s physical intervention and leaves them for Monday, when returning workers will find two nearly finished parts waiting.

“Even skilled programmers can benefit from this kind of time saving.” Eric Ostini, GF Machining Head of Business Development, North America

Additionally, EDM programmers planning for lights-out operations can dramatically reduce the time it takes to program parts.

Unlike machining, which can benefit from numerous part-moving technologies, unattended EDM work relies almost exclusively on batching — setting up multiple workpieces in a single work envelope. One limiting factor for this method is the programming: With standard controls, users have to separately program each part, including programs for moving the wire between workpieces. This means that even programming identical parts involves programming separate sets of coordinates and wire movements, including code to move the wire back to the origin point.

Programming G-code can be time-consuming, especially for complicated parts. However, the ability to save, recall and adjust G-code automatically makes dynamic programming an attractive option for many shops.

Using the dynamic programming function, users can highlight saved jobs, input the part positions and hit start. The control automatically generates the code for the program, including all non-cutting movements. “Even skilled programmers can benefit from that kind of time saving,” Ostini says.

While not rising to the level of artificial intelligence, these capabilities enable the machine to autonomously generate code, saving the operator time. Users must still program part geometries and cutting paths into the machine using their expertise to identify efficiencies that benefit the shop.

However, the control’s ability to save this information and generate code for later use eliminates redundant work for skilled programmers, enabling them to get machines running faster and move on to more work. As Ostini puts it, “Dynamic programming enables the intermediate or beginner operator to function at the level of a skilled programmer and enables the skilled programmer to make more efficient use of their time.”

Related Content

Electrical Discharge Machining in Ten Articles

This roundup of the top ten Electrical Discharge Machining articles on Modern Machine Shop covers the wide range of EDM topics.

Read MoreEDM Network Wire EDM Features Four-Axis Cutting

The EDMMax 434W fast-wire EDM includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts.

Read MoreNew Look, New Feel, New Robots at System 3R

Are AMRs the next big trend in job shop automation? System 3R’s IMTS booth will emphasize both its specialty EDM tooling and its automation products, including an autonomous moving robot.

Read MoreMWI Introduces Wire EDM Consumables Designed to Maximize Energy Efficiency

Blac Technology’s specialized composition is designed to provide uniform distribution and embedding of particles throughout the surface.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)