5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Share

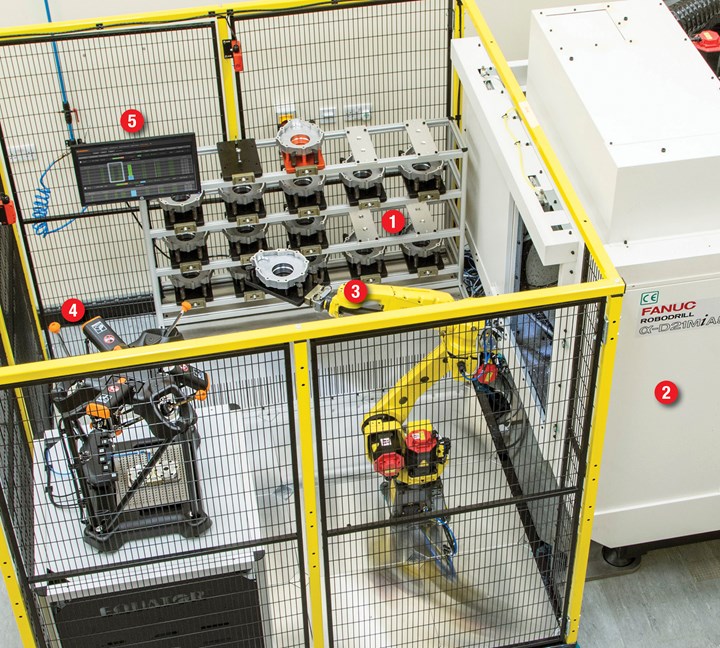

The common thread that ties together any digital-first architecture for shopfloor automation is software that can leverage data from connected shopfloor devices. In this photo of a fully automated cell, the Renishaw Central software platform achieves end-to-end process control via multi-directional data flows between the software, a machine tool, a robot and a gaging system.

To create the Renishaw Central system, the company examined years of its own historical production data, using Microsoft’s Power BI data visualization tool to build dashboards and create custom reports of historical and real-time data from the company’s production equipment. In this image, the gaging machine is programmed to measure part features and, when a measurement departs from the nominal value for a given feature (indicating tool wear) the company’s Intelligent Process Control (IPC) system sends compensating tool offsets to the machine tool CNC. In this way, the system is able to transform connected data into actionable information. Here’s how it works:

- Incoming materials or workpieces from earlier stages are stored on racks alongside finished parts.

- Closed-loop CNC machining uses feedback from Renishaw Central to update tool offsets and variables, maintaining process control. This extends the usual functions of in-machine tool setting and spindle probes, which now also send data to Renishaw Central. This data can be compared and corroborated with data from shop-floor gages and CMMs.

- A part transfer robot automates the movement of workpieces between storage, the CNC machine, and a near-line gaging system, allowing the manufacturing cell to run unattended. The Central platform monitors the quality of parts and processes, halting operations if they go beyond set limits. This automation ensures consistent quality without the worry of producing uncontrolled scrap.

- A Renishaw Equator shopfloor gage delivers measurement and dimensional feedback to the Central platform, allowing for rapid quality control after machining and providing the data needed for process adjustments before machining additional workpieces.

- The Central dashboards offer different overviews of the manufacturing process, from tool setting and in-machine inspection, to Equator shop-floor checks and IPC configurations. This helps to ensure a closed-loop process and enhances confidence in automated settings.

Related Content

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.