Share

Inefficiency is the enemy of successful quotes. When Temco Precision Machining noticed its quotes consistently came in too high, it looked to FANUC’s machine monitoring software MT-LINKi for assistance. But the insight it granted proved useful to much more than just quoting.

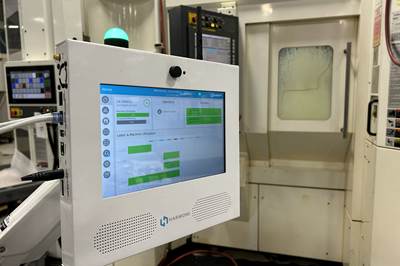

Temco has standardized on FANUC controls. Temco Vice President Maurice Collins theorizes that most people in the industry are familiar with this control style, so training time is minimal. Temco assigns training videos to new users to help them understand FANUC controls, with shopfloor mentors helping fill in the gaps. Images courtesy of FANUC America.

High Precision, High Requirements

Temco is a precision machining company that operates in the aerospace, defense and commercial markets, among others. It handles both high-mix, low-volume manufacturing and traditional production with materials from aluminum to stainless steel to graphite. Its tolerances reach 0.0004 inch, and it runs about 60 CNC mills from different machine manufacturers alongside another dozen wire EDM machines.

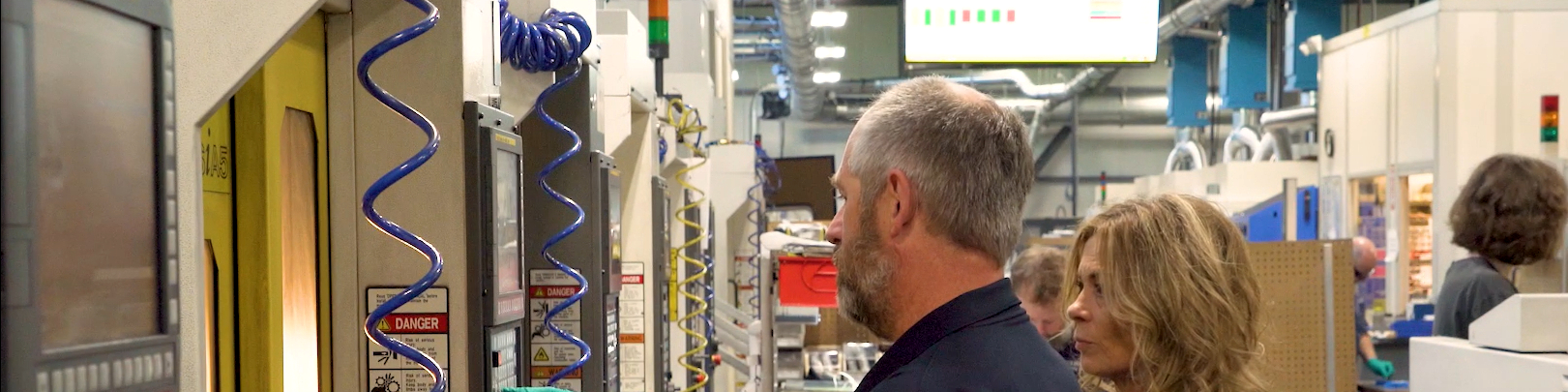

In short, Temco needed machine monitoring software compatible with a wide variety of machines and interfaces, with the ability to dive into any machine’s operations when necessary. Ensuring smooth operations also required local storage, out of the box reporting capability and a shopfloor view both useful to machinists and informative to visiting potential customers.

Of the software Temco considered, it found MT-LINKi best met these requirements. A large number of the shop’s machines are FANUC-manufactured (with even more using FANUC controls), further improving the software’s suitability. Integrating systems with newer FANUC controls was relatively simple, requiring only a single button-press once the connections were ready, and the machines were up and running with the software within a day of starting installation.

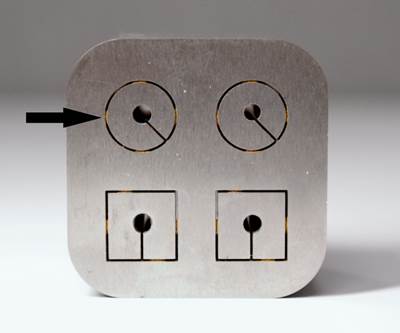

The most common milling machines on Temco’s shop floor are FANUC RoboDrills, with RoboCuts serving as its most common EDMs. MT-LINKi helped Temco identify a program that was inefficiently programmed for one of its RoboCuts, and revisions boosted the machine’s productivity between 200 and 300%.

Nailing Down Cycle Times

Production improved by 10-15% out of the gate, according to Temco Vice President Maurice Collins, as operators running multiple machines simultaneously found the visual aid of the software useful for keeping track of their machines’ statuses. The company installed MT-LINKi on the rest of its mills and on its EDMs through OPC-UA and MT-Connect protocols.

While not as quick as FANUC’s auto-configure option for analyzing axes, spindles and paths, these machines were also up and running on the same day as installation. Temco has also added eight 85-inch TVs across the shop floor to help operators keep track of their machines (and show off their utilization to potential customers).

Adding machine monitoring to the shop’s wire EDMs has resulted in even larger productivity gains. While the long cycle times of wire EDM make even slight errors extremely consequential, they also make inefficiencies equally outsized.

Temco quickly noticed that a job that took 9 hours to complete on one machine was taking 12 hours to complete on a newer, ostensibly more powerful machine. With the problem identified, the shop’s programmers could diagnose the issue, soon concluding that machine was using an older version of the part program that didn’t take advantage of the machine’s newer features. They were also able to better schedule out when operators needed to hit confirmations, eliminating a common source of downtime. A few months into adopting machine monitoring software, productivity had nearly doubled on the wire EDMs.

Alongside the out-of-the-box features, Temco customized the software to add an additional two statuses to the default six. The custom “manual” status enabled the shop to track when operators perform jogs or other manual operations, while the “warm-up” status covers prep time heating tools to ensure consistent performance on high-tolerance parts.

Clear definitions of uptime and downtime also enabled the shop to be more strategic in scheduling breaks and helped it save electricity by simplifying how to check whether any machines are on warm-up mode overnight, as the shop does not currently schedule a third shift. Alongside the custom statuses and mode monitoring, Temco worked with FANUC to implement the software on support machines such as degreasers, further improving management’s insight into shopfloor process.

Temco Operations Manager Steve Bairam says that FANUC controls include features that make them well-suited for precise, high-speed five-axis machining. Multiple levels of high-speed machining are built into the controller, and it also supports five-axis synchronous cuts.

Machines of Tomorrow

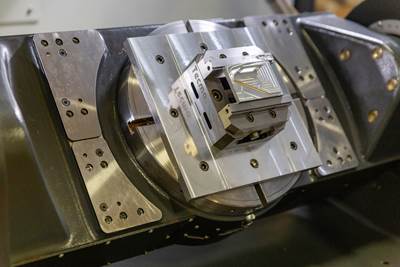

Full insight into productivity on a machine-by-machine basis has led to more than just machine optimization; it has led to process optimization. On the surface, machines with pallets are more efficient and more productive, if more expensive. Yet when the shop looked into its data to determine into which jobs were most successful on which machines, it noticed that several jobs that required vacuum workholding had been assigned to a pallet machine. This workholding method nullified the largest advantages of the pallet system.

So, despite the non-pallet system appearing less efficient on paper, Temco bought a mill without a pallet and reassigned vacuum workholding jobs to it, opening up space on its pallet-equipped machines for jobs that benefit from pallets. This strategy increased productivity, further enhancing the shop’s ability to fulfill orders and supply accurate quotes.

Quotes, not Estimates

After just over a year of monitoring machine throughput and optimizing its machines, Temco began basing its quotes on its new productivity in November 2022. The takt rate improvements from this change enabled the shop to produce ahead of schedule on one multi-year contract using the wire EDMs — so much so that the shop was able to support a separate multi-million dollar contract that also used these machines.

Related Content

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreGive Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

Read MoreLeveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

Read MoreRead Next

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreA Stitch in Time—A New Core Retention Function for Wire EDM

When running a wire EDM such as the FANUC RoboCut C800iB, an automatic routine in the CNC program adds a "stitch" at a few strategically placed locations around the periphery of the core. By holding the cores in place until the entire job is finished, multi-workpiece cutting processes are able to run in an extended, unmanned mode.

Read More

.jpg;maxWidth=300;quality=90)