Top Shops Are Data-Driven by Definition

CNC machine shops at various stages of digitalizing their operations share a commitment to evidence-backed decision-making.

Share

The stories about this year’s Top Shops Honors Program could be reassuring for anyone who is anxious about being left behind as digitalization changes our industry. Each of these four shops stand out as an example of what a successful CNC machining business looks like, and all are committed to evidence-backed decision-making and continuous improvement. However, their recognition as honorees has relatively little to do with the capabilities typically associated with “smart” manufacturing: namely, networked equipment and the automatic collection, exchange and analysis of shopfloor data.

Forest City Gear, one of this year’s Top Shops honorees, relies on a process driven largely by paper printouts. Photo by Brent Donaldson.

This includes the winner in the technology category: Reich Tool & Design (RTD). This company has ambitious plans for Industry 4.0, including GPS-guided robotics and automation that that interfaces with enterprise resource planning (ERP) software. Meanwhile, more flexible systems, particularly collaborative robots, are changing how leaders think about automation — and, by extension, the future of the company. However, collaborative robots alone do not make this company a Top Shop, nor do investments that have yet to be made. RTD also stands out for the diversity and sophistication of the technology already on the shop floor, as well as how it uses that technology.

Another honoree, AccuRounds, has been using a machine monitoring system for a few years now. This timeframe is more than long enough to impact the performance metrics that earned the company “Top Shops” status this year. In fact, MMS published a case study about the impact of machine monitoring at the company more than a year before its leaders filled out our survey. And yet, even in that case study, much of the focus was on the shop’s approach to people — the very same thing that led to its later selection as the 2021 Top Shops Human Resources category honoree.

Similarly, business strategy winner ACR Machine Co. has made significant information technology investments. With new ERP software, machinists are logging into terminals rather than punching cards, and tracking performance is easier. The culture has even changed. However, ACR’s recognition as a Top Shops honoree is more about what made this change possible: goal-setting, financial planning, and a commitment to putting every penny back into the business as part of a renewed focus on growth.

Finally, we have Forest City Gear (FCG). Devoting an average of 40% of gross annual sales to new machine tools, FCG is a high-tech company by any standard. However, this company has earned recognition for a meticulous process that depends heavily on paper printouts — an aspect of the shop’s process that is unlikely to change any time soon.

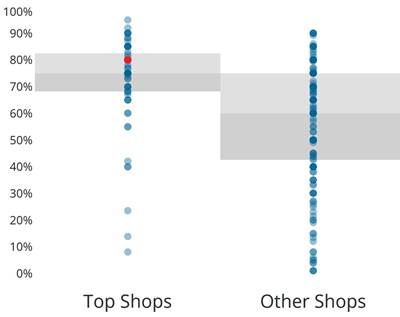

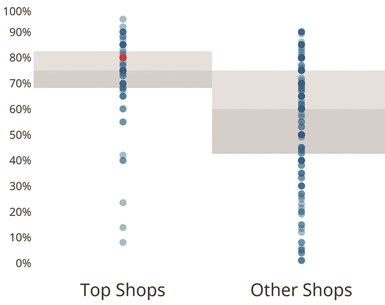

Represented by the red dot, the shop in this graph from a custom report from 2020 has better spindle utilization than most other survey-takers and even most other Top Shops.

Although these shops are at different points in their data-driven journeys, all four are unquestionably committed to using data to improve their businesses. Otherwise, their leaders never would have filled out the detailed benchmarking survey that led to their earning “Top Shops” status in the first place. Similarly to the latest technology, benchmarking is a means to an end for them and others who fill out the survey. It is a tool, and the best tools tend to be worth the effort required to learn to use them correctly.

In this case, of course, the effort consists not of learning new software or other technology, but of answering questions — lots of questions. I’m not supposed to say so, because we want as may shops to fill out the survey as possible, but answering these questions takes time. This is what is required for our dataset to be so robust, and for the resulting reports to be so revealing. Each is customized for the individual survey-taker, complete with graphics and lists of specific metrics (spindle utilization, labor turnover rate, order lead time and so forth) identifying areas of strength, underperformance or performance on par with the rest of the survey-takers.

At this point, benchmarking becomes more like technology in that things might get uncomfortable. People who sell machine monitoring systems are full of anecdotes about shellshocked shop owners learning for the first time that their processes are not as productive as they thought. Benchmarking might evince similar reactions. Those who are truly ready to leverage either tool must resolve to face the reality of the results unflinchingly, then plan and act accordingly.

Filling out a survey might not be what comes to mind when you think about “data-driven manufacturing.” Nonetheless, in terms of targeting improvement efforts, the resulting insights might be no less impactful than metrics pulled from shop-floor CNCs. If you’re inclined to fill out our survey, and to use it as the tool it is intended to be, you’re likely to have the right mindset to succeed in today’s data-driven manufacturing world. You might even be able to call your business a Top Shop.

Related Content

How a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

Read MoreBenchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read More2024 Top Shops Honorees Announced

Modern Machine Shop Recognizes Excellence in Manufacturing with Annual Award

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Benchmarking Becomes a Call to Action

A means of measuring performance evolves into a tool for catalyzing change as Modern Machine Shop’s Top Shops program matures.

Read MoreAll Top Shops Are Winners

Standing out in one category is not enough to earn a spot among the highest-performing CNC machining businesses.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More