Large Part Machining

The Part Is Longer Than The Lathe

Here is one custom machine builder’s system for producing a 40-foot part that has to be passed through the turning center and out the other side. INCLUDES VIDEO.

WatchMachining At Mach 3

Airbus invested in abrasive waterjet for machining CFRP components. Here is why.

Read MoreSide Turn-Milling Of A Massive Crankshaft

This video footage showing the machining of a massive crankshaft suggests some of the possibilities of turn-milling. Not all shops realize possibilities such as this even on their own smaller-scale turn-mill equipment.

WatchGetting New Business with Big Machines

These shops saved themselves from dependence on the declining automotive sector thanks in part to their commitment to large-scale machining capacity.

Read MoreThe Basics Of Producing Big Parts

This Florence, Kentucky-based machine tool builder uses its own equipment to produce machine tools. Here’s how they succeed at big-part machining on a large five-axis machining center.

Read MoreComposites Keep A Big Machine Busy

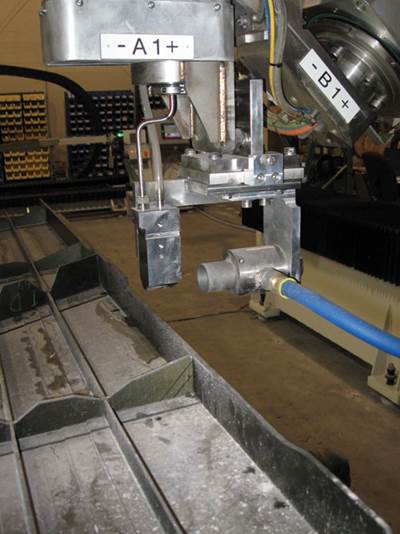

On-machine inspection is part of the way this shop machines large composite structures efficiently.

Read MoreAbrasive Waterjet Helps Make Composites Affordable for Boeing

Boeing overcame fixture costs and other challenges of machining large composite parts by opting for waterjet instead of milling.

Read MoreMore Than Big Machines

This shop specializes in very large components such as rotor hubs and support bases for wind turbines. Its lineup of large horizontal boring mills can handle parts weighing 40,000 pounds and 12 feet on a side. However, the shop’s success also lies in other manufacturing resources and strategies. These include material handling equipment, customized tooling, special fixtures and wireless, portable measuring systems.

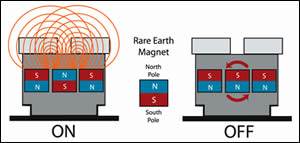

Read MoreAttracted To A Better Way

Modular, magnetic workholding blocks have changed the way this shop approaches the machining of both large and small workpieces. The blocks’ portability allows them to be used on a variety of different machines. Their flexibility often eliminates the need to create custom fixtures.

Read MoreApplying A High Speed Machining Discipline Without The Speed

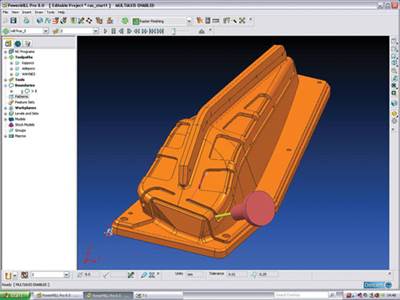

In this shop, high speed machining makes sense at 4,000 rpm. While the disciplines the shop put in place made a new 15,000-rpm profiler dramatically more productive, high speed machining would have remained valuable even if the new machine never came. Acoording to a co-owner of this shop, high speed machining has no need for speed.

Watch

.jpg;maxWidth=400;quality=70)

.jpg;maxWidth=300;quality=90)