Machining At Mach 3

Airbus invested in abrasive waterjet for machining CFRP components. Here is why.

Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreThe hard, solid cutting edge of a conventional end mill poses real dangers to the part whenever a tool such as this is used to cut carbon fiber reinforced plastic (CFRP). The impact and mechanical stresses can produce separation of the layers of material or pull-out of the carbon fibers. That is why, instead of tools with edges, shops often use abrasive milling tools to machine CFRP—tools that look like they are part grinding wheel and part end mill. High spindle speeds give tools such as these an efficient abrasive machining effect.

Yet there is another step beyond this. There is another option that achieves abrasive machining at even faster speeds. While an abrasive milling tool in a fast spindle might reach a cutting speed equivalent to about 50 miles per hour, an abrasive waterjet machine delivers the abrasive across the workpiece at a speed of about Mach 3. The difference is significant to Airbus, among others.

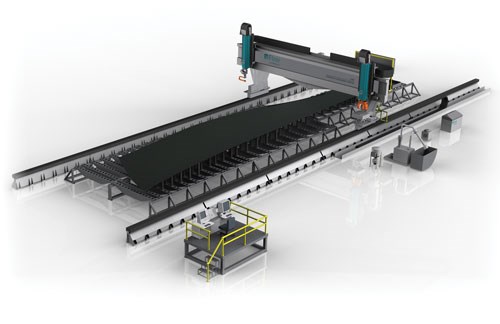

In order to develop lighter, more efficient and more durable planes, Airbus is increasingly applying engineered composite material to aircraft designs. The airframe of the new A350 XWB (“Xtra Wide Body”) aircraft is more than 50 percent composite materials by weight. CFRP components include the wings, fuselage, empennage, spars and keel beam—all of which will be machined using abrasive waterjet. The aircraft maker recently awarded Flow International a $30 million contract to build multi-axis abrasive waterjet machine tools at its Indiana facility for use in aircraft production plants throughout Europe.

Jose-Luis Morazo-Perez is head of A350 manufacturing engineering automation for Airbus, based in Hamburg, Germany. He says the company’s production facilities often use CNC routers and other rotary-tool machines to machine composites. Such machines were considered for this application as well. However, abrasive waterjet offered a clear economic advantage in the A350 XWB application. The abrasive and other consumables cost less than the cutting tools and other comparable consumables that would be needed to mill the parts. The cost of machine time was also less, because the faster cutting means the part spends less time on the machine.

“This was the best economical approach considering both recurring and non-recurring costs,” Mr. Morazo-Perez says.

He adds that further savings are likely to come from eliminating a costly step. Parts machined on a rotary-tool machine typically require deburring, even if the parts are cut with abrasive. But with waterjet, the cutting action is much faster and more thorough.

“Our expectation is that we could eventually avoid the deburring operation,” he says.

In other words, instead of achieving merely acceptable cutting that avoids the worst dangers such as delamination, the company sees hope for machined edges that are clean enough for the composite parts to be considered finished as soon as the waterjet cutting is done.

Waterjet In Action

Mark Saberton, chief engineer for Flow International, says these advantages that Airbus cites—faster cutting and avoiding damage to the workpiece—are among the main benefits aircraft manufacturers seek through machining composites with waterjet. Other benefits include:

• No dust. Fine dust from machining composites can infiltrate controls and other electronic equipment in the shop. It also makes the shop grimy and unappealing. With waterjet, this dust is contained and controlled. For the most part, the dust is carried away with the water, from which it can later be removed.

• No heat-affected zone. Delamination and fiber pullout are not the only dangers of mechanical cutting. Another is heat, which might melt the matrix of CFRP. But waterjet is inherently a cool process. Heat generation is slight, and the water transports the heat away.

• No rigid clamping. An unsupported edge of a CFRP workpiece is prone to vibrate during milling. For this reason, machining of composite structures on routers or similar machines often involves elaborate tooling designed to carefully and rigidly clamp the work at every trimmed edge. Vacuum fixturing built to the precise contours of the part is common. But with abrasive waterjet, the force of cutting is slight. The force also pushes down against the support beneath the part. Therefore, while programmable workholding is sometimes used (see below), rigid custom tooling is not required.

Aircraft Equipment

That “programmable workholding” is one of various features Airbus specified to allow its waterjet machines to be adapted to the particular needs of complex aircraft parts. Work is supported atop a flexible header system consisting of an array of effectors that resembles a bed of nails. Each effector’s vertical position is set independently, so the overall array can follow the contours of the part. Changing from one part number’s positions to the programmed effector positions for a different part takes only about 2 minutes, Mr. Saberton says. This compares very well to the hours that might be required to move one custom fixture off the machine and replace it with another hard fixture. Mr. Morazo-Perez says Airbus initially questioned this approach to workholding—worrying in particular whether the flexible tooling would stand up to the water over time. The company became convinced after visiting shops using similar programmable workholding on waterjet machines in the U.S.

Other machine features particular to aircraft abrasive waterjet machining include:

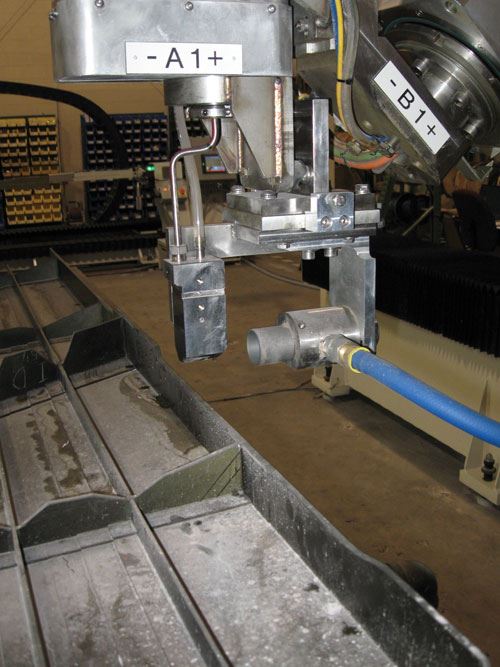

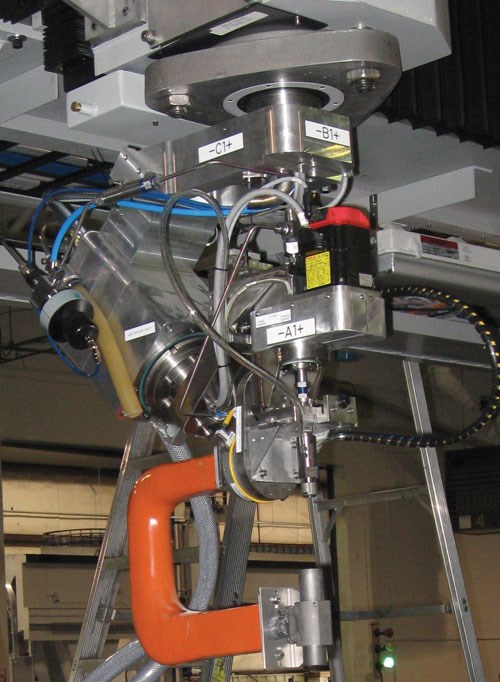

• Side-fire nozzles. Aircraft skins can include small ribs and stringers that impede access. The machine’s ability to switch to a nozzle that redirects the jet to the side can be useful for cutting within these tight spaces.

• C-catcher. The contours of aircraft structures can double back upon themselves, meaning the jet of water exiting the cut might hit some other surface of the part. To prevent this, a C-shaped catcher (see photo) can intercept the exit side of the jet. A consumable inside of this device absorbs the energy of the jet so the water can be captured and reclaimed.

• Rotary spindle. As Airbus indicated, rotary-tool machining remains useful in many composites applications. In fact, certain features must be machined in this way. While waterjet can machine a hole, for example, it can’t machine a countersink. Therefore, some abrasive waterjet machines incorporate rotary spindles for such needs as this. The rotary spindle is also useful for marking tools.

Mr. Saberton says one other, even more significant advantage of having such a spindle available is that it allows the machine to use a probe. This can permit further consolidation of steps, he says—allowing the waterjet machine itself to inspect the part before it leaves the machine.

Related Content

Muratec Hybrid Machine Combines Punch Press, Fiber Laser

The MF3048HL combined punch press and fiber laser provides precise cutting, punching, tapping and forming operations on a diverse range of materials.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreFlow Waterjet Systems Enable Complex Part Cutting

The Mach 200c enables bevel and five-axis cutting of most materials with up to 60-degrees of motion.

Read More3 Lessons Job Shops Can Learn From Laser Cutters

This laser-cutting “job shop” designs its processes to make high-mix, low volume work profitable.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)