Attracted To A Better Way

Modular, magnetic workholding blocks have changed the way this shop approaches the machining of both large and small workpieces. The blocks’ portability allows them to be used on a variety of different machines. Their flexibility often eliminates the need to create custom fixtures.

Share

Shops make a number of fundamental decisions while determining how best to machine a new job. In the case of repeat work, progressive shops eventually identify new strategies or equipment to make the setup and machining of those parts more efficient and less time-consuming.

The adoption of atypical workholding devices by Five-Axis Industries offers a case in point. A particularly large part that was a hassle to fixture drove the Seattle-area shop to find a more effective means for securing the part during machining. Although the conventional tooling-plate method it had originally devised proved adequate in terms of generating good parts, a total of 7 days was required to create a fixture, set up the job and machine a new part.

Now, the shop uses a magnetic workholding system in which multiple permanent-magnet blocks are located at specific points under the large steel part. Not only did this new workholding method reduce the part production time from 7 to 2 days, but it also was versatile enough to secure other ferrous parts of varying sizes on different machines with comparable results.

Modular Magnets Secure A Marine Component

Erick Ellstrom is vice president of the shop that serves the aerospace and marine industries, among others. The shop is part of Ellstrom Manufacturing, which sponsors an unlimited hydroplane boat-racing team. Mr. Ellstrom is both crew chief and team manager. Five-Axis Industries machines various boat and turbine-engine components for this team and other hydroplane racing teams and engine builders.

Not surprisingly, the aforementioned difficult-to-fixture part is used in a marine application. It begins as a rectangular blank of 4340 steel that weighs 2,200 pounds (it weighs 1,300 pounds after machining). The shop has been successfully machining this part for years, but Mr. Ellstrom says it never developed what he considered an effective way to secure it for the machining operations required on both part faces. Mr. Ellstrom admits that the part is not particularly difficult to machine, although it is big and heavy and has a taper on one face that must be accurate to a tolerance of 0.002 inch along the part’s entire 80-inch length.

Originally the shop built a base fixture (a time-consuming process) and then bolted the workpiece to the fixture through tooling tabs that eventually were machined off of the part. Setup time using this fixture was lengthy, and a second, long setup process was necessary after flipping the workpiece to access the other face. In addition, because the workpiece was secured only at points around its perimeter, the center section was “live.” That is, harmonics during machining had to be minded so as not to adversely affect surface finish and machining accuracy.

The shop considered using vacuum workholding chucks, but those devices would have required individual fixture plates for each part, too. Electro-permanent workholding chucks were another option, but the marine part would have needed a huge chuck and electrical supply at the machine to operate the chuck. (Electro-permanent chucks require an electric jolt from a control box to “turn on” the magnet. The electrical connection can be removed from the chuck after this step and the magnetic holding force will continue.)

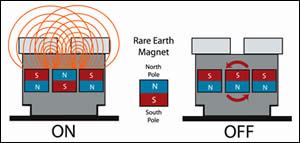

The shop found a solution in the modular, permanent-magnet workholding blocks available from Earth-Chain USA (Indianapolis, Indiana). The compact workholding blocks can be clamped on a machine’s table wherever they are needed. The number of blocks required depends on the size of the workpiece. Within the blocks are north and south poles across which magnetic energy (flux) flows. When a ferrous workpiece is located between magnetic poles, the flux enters the part and induces a polarity in the part that opposes the magnet. This causes an attraction between the part and magnet, and that attraction provides the holding force (see drawing on page 87).

Unlike electro-permanent chucks that require electricity to switch the chuck into the “on” position, operators positively engage the magnets on these blocks by using a wrench to turn an on/off switch. The magnetic holding power continues until the switch is turned to the off position.

During setup of the large marine part, Five-Axis Industries first positions a number of workholding blocks in a specific array on a VMC’s worktable. Each block is topped with replaceable soft jaws. The VMC then decks the top of each block so all are flat in relation to each other. After that, the workpiece is loaded onto the blocks using a crane and permanent-magnet lifting device. The lifting device works similarly to the magnetic blocks and has a lever to switch holding power on and off. Once the workpiece is installed on top of the blocks, an operator turns the power switches on the blocks to magnetically secure the workpiece to the top of the blocks.

Prior to loading the steel blank into the machine, the shop first hones both faces of the workpiece, which is done to help ensure that the precise 0.002-inch taper will be produced. Next, the top is rough-milled and then finish-milled using an Ingersoll face mill. The part is then flipped to allow drilling, reaming and finish-milling of its second face.

Expanded Role

Five-Axis Industries has a number of the magnetic workholding blocks, and it uses them on various machines to secure workpieces that have different sizes. Mr. Ellstrom says the blocks offer setup flexibility because they can be positioned as needed on a machine’s table to fit within the profile of many workpieces. The shop also uses the blocks not only to reduce setup time on ram EDM equipment, but also to eliminate the need for dedicated fixtures. The blocks are effective in holding such individual small parts because their poles are closely located together and do not require a significant amount of surface area to obtain the requisite holding power. (Maximum holding force for the largest of these blocks is 4,620 pounds.)

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Vacuum Workholding Method Fits New Machining Strategy

Increased demand for armor plating components led this shop to completely revamp its machining technique. Rather than machining individual workpieces, the shop produces multiple components nested in an aluminum plate. A custom vacuum workholding system plays a significant role in this new strategy.

Read MoreApplying Creative Workholding Techniques

Not all parts can be fixtured by conventional workholding methods. Here are a few examples of ways that shops secure feisty workpieces for milling and turning operations.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More