Side Turn-Milling Of A Massive Crankshaft

This video footage showing the machining of a massive crankshaft suggests some of the possibilities of turn-milling. Not all shops realize possibilities such as this even on their own smaller-scale turn-mill equipment.

Share

Takumi USA

Featured Content

View More

The video clip on this page shows a milling pass that is heavier and more extreme than any cut the typical machine shop is likely to make. A forged crankshaft with a swing of 2.78 feet (this is a shaft for a ship, not a car) is side-milled along its web at a 0.2-inch radial depth of cut and an 11.8-inch axial depth of cut. The pass is literally “turn-milling,” in that the operation is both turning and milling at once. The shaft rotates while the milling cutter spins. The thickness and volume of the material removal can be heard once the chips fully start to rain out of the cutting zone. Play the video to see for yourself.

Again, only a small percentage of shops will ever machine a part this large or take a cut that has a 2.36-square-inch cross section. Still, the footage is interesting even well below this application size because of what it says about the capabilities of so-called “turn-mill” machines. Too many shops that own and use these machines think of them as turning machines that become capable of light milling or drilling once the part rotation stops. But when the different types of machine movement are coordinated, when turning and milling are combined into one, what additional part-processing strategies or part geometries can become practical? The answer will vary from shop to shop—and an article under “Editor Picks” at right has more to say about this question. However, the overall point is this: Turn-mill machine tools are often underutilized, and they may yet reveal themselves to be effective for a much broader range of parts than many shops assign to them today.

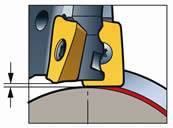

Crankshaft Cutting

The cutting tool used in this particular turn-milling pass is a 4.72-inch-diameter milling cutter from Austrian cutting tool supplier LMT Boehlerit. It has approximately 80 inserts. As the video shows, the tool comes close to cutting along its entire length as the web reaches its full apex of rotation. While the insert spacing visible in the photo of the cutting tool may appear random, this spacing actually accounts for the particular motion of the part. Because the workpiece rotates past the tool and because the tool is so long, circumferential speed varies significantly along the tool’s length. The tip of the tool sees a different feed rate than the base of the tool. The tool’s insert spacing was designed to account for this.

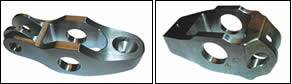

The machine tool is an “mpmc,” (Multi-Product Machining Center) from Weingärtner Maschinenbau GmbH—also based in Austria. Among the massive parts produced on turn-mill machines such as this one are crankshafts for ships and trains, including the different styles of shafts that produce electrical power on ships and propel their motion through the water. The machine tool can accommodate parts as big as 36 feet long and 4.9 feet in diameter. For a crankshaft part, the weight of the workpiece could be 20 metric tons.

Yet Weingärtner machine tool division manager Gerald Steininger says the mass and scale of the parts are not the only factors that contribute to machining challenges in these applications. Ultimately, instead of the bigness of the parts, it may be the smallness of the tolerances that is the most impressive. These large parts often have to be held to tolerances that would be considered difficult on small parts. A 23-foot crankshaft with a swing of 3.3 feet could require the crank to have a roundness tolerance of 0.0008 inch. Just the weight of the part alone—even before any cutting forces are applied—could produce deflection equal to many multiples of that tolerance value.

Mr. Steininger says holding fine tolerances on such large parts involves a variety of technologies that go well beyond what conventional turn-mill machines require. The design and stiffness of the machine are important elements in achieving this precision, but these are just the start. Other necessary components include:

● Steady rests that are precisely position-controlled in three axes (X, Y and Z) to ensure that the shaft remains clamped in the correct position.

● An HSK 125 toolholder interface, with the tools not just hydraulically clamped, but also hydraulically released from the spindle. The machine can load tools as heavy as 36 kilograms directly from the chain-type magazine. (Boring bars weighing 100 kilograms or more can be parked four-at-a-time on top of the headstock.)

● An integrated tool shuttle that allows the tool to be changed at any Z-axis position of the machine. Any tool in the magazine might have a length of up to 47.2 inches.

● Closed-loop inspection. Through probing, both the workpiece and the tool are routinely measured before any finishing pass, with machining offsets precisely updated as needed. At this scale, even deviations that are very slight relative to the size of the tool or part could cause the cut to break tolerance. In-process measurement is therefore vital for maintaining control.

“One of these crankshafts could easily exceed $500,000,” Mr. Steininger says. “To make an error in the final stage of machining would be costly.” So, while the machining hardware keeps the process stable, the process also includes these measurement safeguards to further protect against error.

The last point suggests an idea that may also be useful for turn-milling at almost any scale. Few shops may deal in half-million-dollar parts, but making greater use of the turn-mill machine as an alternative to using various machines in series does consolidate more value-added machining into one place. Ensuring that the value does get added during this machining might involve a more thoughtfully designed process with more careful process control. The shops able to precisely engineer their processes in this way will find themselves taking turn-mill machines to more efficient and profitable extremes.

Related Content

Rego-Fix Appoints New Global Aerospace Specialist

Sherman D’Souza will provide global customers with access to Rego-Fix research, development and technical support teams to create and supply toolholding solutions.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreAFRC, ATI Partner to Boost Aerospace Materials Innovation

ATI Inc. has joined the University of Strathclyde’s AFRC as a tier one member, aiming to develop metallic alloys that support sustainability in the aerospace sector.

Read MoreRead Next

Applying Turn-Milling

Combining a rotating tool with rotating work produces a machining operation that is distinct from standard turning or milling.

Read MoreTurning Is Optional

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)