Large Part Machining

Large Wire EDM Unit Gives Shop Room to Grow

This wire EDM job shop in Wisconsin acquired a submerged cutting wire machine that lets it handle larger, taller workpieces than just about any other job shop in the country. The new machine has a “column-up” option that adds a riser block between the X-axis saddle and the Z-axis column casting to give it exceptionally tall cutting capacity. The machine was installed in November 2007.

Read MoreVacuum Workholding Method Fits New Machining Strategy

Increased demand for armor plating components led this shop to completely revamp its machining technique. Rather than machining individual workpieces, the shop produces multiple components nested in an aluminum plate. A custom vacuum workholding system plays a significant role in this new strategy.

Read MoreBig Inspection With Little Difficulty

A portable laser tracker let this shop increase not only its machining range, but also the range of its services to customers.

Read MoreUnder Pressure

Using an integrated, single-window solution can alleviate programming bottlenecks, making the transition from design to manufacturing smooth.

Read MoreRealizing Large-Scale Savings On Large-Scale Parts

Converting big square bars to largely round tie bars used to require 24 hours per piece at Oak Products. The Sturgis, Michigan, company can now complete the same job in 8 hours. How did the company slash its machining times and realize substantial cost savings? Oak attributes the turnaround to process re-engineering involving aggressive mill-turning and tooling geared to stand up to the challenge.

Read MoreTurning The Long And Difficult

This shop has made large turning work its specialty. In proving to its customers that it can perform this difficult work, it has started to win more "standard" machining jobs.

Read MoreMove The Program Instead Of The Part

A complex five-axis part with hard-to-reach datums is machined in two setups instead of eight, thanks to a process that rewrites the tool paths to match the part's position.

Read MoreThinking Big

This shop specifies large machine tools for the machining possibilities of the future. To prepare for the feed rates the shop expects to use one day, the latest large gantry mills apply linear motors on all three linear axes.

Read MoreThe Multi-Process Machine Mindset

Installing a machine tool that combines milling, turning, boring and other processes changed this job shop’s outlook.

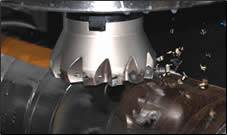

Read MoreTangential Milling Helps Foundry Speed Operations While Reducing Costs

There are always exceptions to those 'hard and fast' machining rules. A tripling of edge life and a 3-to-1 reduction in cutter count on a tough-cast steel milling job at Harrison Steel Castings Company (Attica, Indiana) proves this.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)