Large Part Machining

Shops Serving Oilfield Customers Appreciate Retrofits

Buying new is nice, but there are reasons why retrofits make sense for shops serving the oilfield industry.

Read MoreA Modular Clamping System for Bulky Parts

Here’s one fixturing alternative for clamping large workpieces such as mold and fracking components.

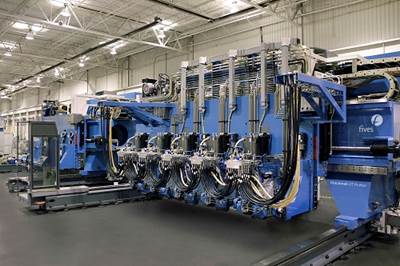

Read MoreProfiler Expected to Exceed 100 Cubic Inches per Minute in Titanium

Five-axis, five-spindle machine aims at reduced cost per piece for production of large aircraft components.

Read MoreA Novel Modular Clamping System

This clamping system minimizes setup times, enable a machine to access five sides of a part and provides highly repeatable positioning for bulky components.

Read MoreLaser Encoder Feedback for 40-Meter Wing Parts

Large machine travels, long machining cycles and changing aircraft manufacturing precision demands necessitated a non-contact approach to machine-tool position feedback.

Read MoreThe Million-Dollar Job

A shop specializing in large parts describes the most expensive single order it ever shipped.

Read MoreVideo: Horizontal Boring Mill Turns 23-Foot-Diameter Part

This shop leverages large-scale multitasking machines. Learn why, and see one of its horizontal boring mills turning a terribly big mining industry part.

Read MoreMultitasking's "Big" Advantage

As demonstrated at this Cincinnati-area shop, machines that both mill and turn shine brightest when workpieces are massive.

Watch“CNC Retrofit” Often Means More

This video testimonial provides an inside look at the myriad benefits Major Tool & Machine has realized from a new CNC platform—but like other, similar projects, implementing that platform required a complete motion system overhaul.

Watch

.jpg;maxWidth=300;quality=90)