-

SPONSORED

-

-

-

-

-

MMS Blog

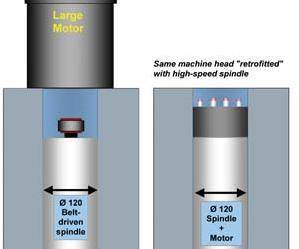

Increasing Torque For A High Speed Spindle

Torque, not power, is the most important characteristic for determining the cutting performance of a spindle. Increasing spindle torque for a high speed machining center ultimately affects not only the choice of spindle but also the design of the machine.

Read MoreGetting To Know Grob

With some familiar names in the machine tool building business fading away recently through mergers, acquisitions, or shutdowns, it may be interesting to learn of an unfamiliar or little known machine tool builder.

Read MoreThe Case For Copy Milling Cutters

The round-insert 'button cutter' can bring a high metal removal rate to a low horsepower machining center.

Read MoreGetting In Gear With An Automated Cell

This production cell embodies several unusual but very effective concepts for keeping process variables under control with little operator intervention.

Read MoreInternal Grinding Spindle Listens To See

This company has taken the use of acoustical technology for grinding machines in a different direction. It has placed a wide frequency acoustic sensor directly into the high frequency spindle of an internal grinder.

Read MoreWelding On A Machining Center

Multiple-process machine tools generally combine two or more processes for metal removal. A lathe may have milling capability, or a machining center may perform grinding. But what about combining metal removal and metal joining in one machine? A process called 'friction stir welding' permits exactly that.

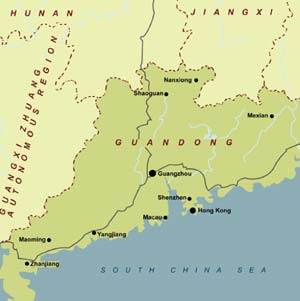

Read MoreChinese Competition In Die/Mold

For several years, the buzz among American moldmakers has included the persistent complaint that competition from China and other Asian nations is eroding business conditions.

Read MoreMoving Toward Complete, Automated CAD/CAM Solutions

Best known for its machining software, UK-based Delcam is adding more software products for design and engineering. The company's explicit goal is to be 'a provider of complete, automated CAD/CAM solutions, taking complex shapes from concept to reality.

Read MoreTurning The Downside Up

An Ohio shop uses inverted-spindle machines to improve production of a high-volume part.

Read MoreStringer Solution

To reduce cost while improving quality and reproducibility, Airbus UK decided to implement a fully automated process able to machine a stringer complete. The existing production facility was stripped to its steel framework and adapted for the new process.

Read MoreNew Borders For Swiss-Type Turning

The traditional niche may be too narrow. This shop uses sliding-headstock lathes for jobs that wouldn't normally be run on this type of machine.

Read More

.jpg;maxWidth=400;quality=70)