-

SPONSORED

-

-

-

-

-

MMS Blog

Empowering The Programmer

A project aimed at making military aircraft parts faster shows just how much productivity gain can come from automating the programmer's repetitive tasks.

Read MoreSetting The Stage For Production

This software is an external verification/optimization tool that provides faithful representations of first-run machining processes. This affords the opportunity to rectify machining conflicts before the first chip flies.

Read MoreThe Right Start For A Fine Finish

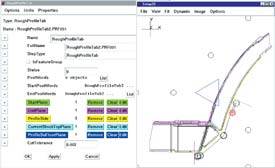

Developers of CAM software have introduced many programming features for the initial removal of excess stock prior to finishing operations. By preparing the workpiece surface for more effective finishing, these roughing routines often determine how efficiently a CNC machining center can perform.

Read MoreWhen Does Hard Turn/Grind Make Sense?

Combining different operations on a single machine tool platform is an attractive and increasingly popular idea. It is in practice, however, not always a plug and play substitution. Optimizing distinct metalcutting operations into a single cycle takes planning and a good understanding of the pluses and minuses of each.

Read MoreCAD Product Takes A New Direction

This CAD software is the first commercial application based on the GeMS++ object-oriented database and memory management tools developed by Honeywell in partnership with the U.S. Department of Energy.

Read MoreCAM at a Crossroads

In the world of metalworking, the CAM part of CAD/CAM (computer-aided design/computer-aided manufacturing) generally means software for programming CNC machine tools. Currently, most of the advances and innovations in CAM software are coming from the smaller software companies devoted to this application.

Read MoreGood Parts, Good Measurements

A machine tool must be capable of generating both, says a software company with a new vision for the role of metrology data in the emerging era of globally integrated manufacturing enterprises.

Read MoreSmall-Diameter Drilling Under Scrutiny

Today's smooth-running high rpm spindles not only allow shops to cut faster with standard tool designs, they also unlock the potential of tiny tools.

Read MoreStart With Waterjet For More Effective Milling

For aircraft components machined out of plate stock, this shop roughs with abrasive waterjet before finishing with conventional milling. Removing roughing from the machining center cuts cost and lead time.

Read MoreA Better Process For Hole Making

This company is in the business of drilling millions of holes in very large parts. As an established manufacturer of heat exchangers and components, the Calgary, Alberta-based company drills an estimated 1.5 million holes per year in metal plates.

Read MoreHarnessing The Quality Engine

Honeywell’s Phoenix aerospace plant uses a dedicated CMM to ensure quality and reduce costs in a high-volume manufacturing cell.

Read MoreConcentric Clamps Hold Down Setup Time

A problem for many shops is that workpiece blanks vary from one to another. This is especially true with molded part blanks such as castings and forgings. These variations require some flexibility from the workholding device.

Read More