-

SPONSORED

-

-

-

-

-

MMS Blog

Process Versus Geometry

Most CAM software can be classified as either fundamentally process-based or fundamentally geometry-based. Understanding this often-overlooked distinction can help you find the CAM system that is best for your needs.

Read MoreAutomation's Extended Reach

The experience of a Windsor mold shop offers an object lesson in machine shop automation. In an interconnected process, automating one aspect of the process offered benefits beyond what the initial planning had led the shop to expect.

Read MoreServing The Human Machine

A New Hampshire manufacturer spurs growth by expanding the medical segment of its business.

Read MoreCoolant Considerations For Medical Machining

While the proprietary nature of the actual metalworking processes used for making 'body parts' tends to be more mystique than technique, there are some things to think about for shops that are looking to do this kind of work.

Read MoreHybrid Grinders For High-End Parts

This manufacturer now applies hybridization to the task of machining complex parts that require flexible grinding configurations. In addition to ordinary face grinding, for example, these machines also have the capability to grind bores, diameters and tapers.

Read MoreUsing The Machine Tool As A Gage

On-machine inspection probing keeps jet engine production flying.

Read MoreSix Advantages Of Horizontal High Speed Machining

Large monolithic aircraft parts may be machined more productively one at a time instead of three at once.

Read MoreWinning The Door Prize

The accuracy of this shop's five-axis gantry-type profiler helped it land the job of machining the engine-bay doors for the F/A-22.

Read MoreOn The Web, March 2003

Volume IV, Issue XVI This month’s OTW Job Shop Site of the Month is the column, and for many good reasons beyond the site itself. CSM Manufacturing is a North Carolina precision manufacturer serving the automotive, transit and other aggregate industries.

Read MoreMoving To Lean Manufacturing

Machining cells have replaced transfer lines as part of a $100-million-plus modernization program to machine drivetrain parts more efficiently and more cost effectively.

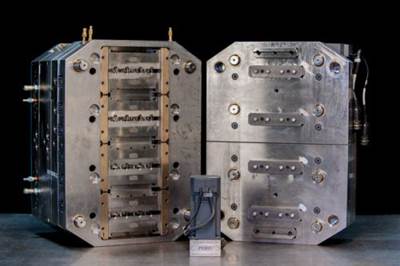

Read MoreProcess Pioneers

There is something different about the molds this shop builds. This puts EDM in a whole new light. These molds are not designed to produce plastic parts, like the typical injection mold. Rather, these molds produce parts in metals such as stainless steel and other alloys.

Read MoreSmall Possibilities

These shop founders focused on what they knew rather than what they had heard about economic conditions when they established their business in October 2000. Their knowledge included the conviction that wire EDM could become the shop’s primary machining process.

Read More