-

SPONSORED

-

-

-

-

-

MMS Blog

Economies Of Scale

Medical implant work is not just small in terms of workpiece sizes. Lot sizes and lead times can also be small when the product is still under development. To compete for implant work, this shop aims to offer cost savings in the face of all of this smallness.

Read MoreCompact Handling Facility Sticks To Basics

Shops consider a number of factors when justifying automated parts storage systems, including cost, required floor space and machining application.

Read MoreCollet System Keeps Cool Under Pressure

Coolant-through tooling is becoming increasingly popular as manufacturers continue to search for new ways to maintain the tight tolerances, high accuracies and smooth surface finishes required for many of today’s jobs. While coolant-through spindles are now a standard feature on many new machines, the machines and tools themselves represent only part of the equation. The interface between the spindle and the tool—a properly sealed toolholder—is just as important.

Read MoreMore Than Big Machines

This shop specializes in very large components such as rotor hubs and support bases for wind turbines. Its lineup of large horizontal boring mills can handle parts weighing 40,000 pounds and 12 feet on a side. However, the shop’s success also lies in other manufacturing resources and strategies. These include material handling equipment, customized tooling, special fixtures and wireless, portable measuring systems.

Read MoreThe Case For Constant Velocity

Constant Velocity Technology uses high speed computer hardware and creative algorithms to enable machine tools to achieve fast, consistent feed rates across complicated 3D surfaces.

Read MoreStriving To Be Partners, Not Shops

The two divisions within this business machine complex parts for the medical and aerospace industries. So in that sense they’re shops. However, in order to grow with their customers, they realized they had to be more than just providers of good parts. They needed to serve as their customers’ manufacturing partners.

Read MoreSteel Ring Catalog

Smalley’s complete product line is featured in one catalog, which includes more than 7,000 standard wave springs, spiral retaining rings and snap rings.

Read MoreLearn From Your Mistakes

Admit it. There have been instances in which an operator’s mistake or a programming error turned one of your shop’s perfectly good cutters into a deformed creature.

Read MoreLending A Hand To The Machining Center

This coolant-operated gripper loads in the spindle like a toolholder, allowing the machining center to lift and move its own workpieces.

Read MoreMeasuring Taper For Toolholders And Spindle Applications

Companies concerned about strict quality requirements regularly check toolholder tapers for wear or inaccuracy because these conditions can jeopardize the results of a critical operation. However, a shop can check tapers quickly and reliably with air gages. These devices can be used effectively without special operator training. For measuring taper in a production environment, few other methods can match the speed and performance of air, as multiple-circuit air jets can be placed in very small taper gages.

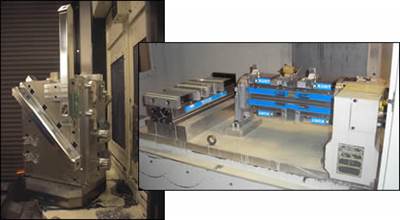

Read MoreAttracted To A Better Way

Modular, magnetic workholding blocks have changed the way this shop approaches the machining of both large and small workpieces. The blocks’ portability allows them to be used on a variety of different machines. Their flexibility often eliminates the need to create custom fixtures.

Read More