Economies Of Scale

Medical implant work is not just small in terms of workpiece sizes. Lot sizes and lead times can also be small when the product is still under development. To compete for implant work, this shop aims to offer cost savings in the face of all of this smallness.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreMicro-machining expertise was not the reason why Protofab Inc. was able to diversify into medical implant machining work. The expertise came later.

Equipment was not the reason, either. This small shop in Petaluma, California, did not have sophisticated equipment for making tiny parts—at least not at first.

Instead, this job shop that was accustomed to other industries and bigger workpieces was able to expand into medical part production for a less obvious reason. The shop won the work and began to thrive at this work in large part because of a workholding strategy that made prototype parts—at any size—more economical.

A Learning “Wall”

Programmer Ferdinand Krall was one employee who spent significant time and effort on developing the shop’s micro-machining expertise. He jokes that the learning curve was so steep, it was more like a “learning wall”—an obstacle that had to be scaled instead of climbed.

The material was hardened 316 stainless steel. Mr. Krall broke tools and scrapped parts as he carefully learned the best ways for Protofab’s equipment to machine micro-size features in this material using tools such as 0.023-inch-diameter drills and 0.025-inch-diameter end mills. He says the machining techniques and cutting parameters that the shop applies to hard steel at conventional cutter sizes do not scale down.

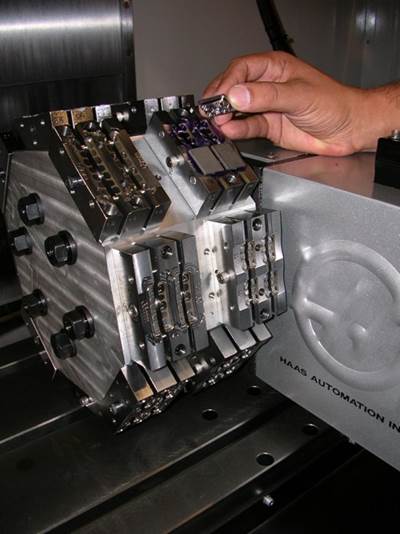

Like the expertise, the micro-machining equipment came with time as well. When the implant work went into full production, the shop was able to invest in its most sophisticated machine tool to date, an SR-20 III CNC Swiss-type turning center from Star CNC Machine Tool Corporation.

Protofab president Mike Maendl says he is confident the shop will buy more machines just like this one as the medical machining portion of the shop’s business grows.

However, buying a CNC Swiss-type machine as a way to pursue the implant machining business would not have worked, he says. In doing this, the company would have overlooked the primary challenge of this work. The smallness of the parts is difficult enough, but at the outset, the smallness of the batch sizes and lead times presented the greater difficulty. Protofab’s customer—a medical device maker preparing to launch a new and specialized product—needed first to refine and prove its design through a rigorous prototyping process. That meant the customer was not looking for a shop that could machine large quantities quickly and inexpensively. The customer was instead looking for a shop that could machine these parts in small quantities quickly and inexpensively. What separated Protofab from other shops that bid on this work was its willingness to automate even for small quantities, and to pass along the savings from automation even during the pre-production stages of the work.

Horizontal To Vertical

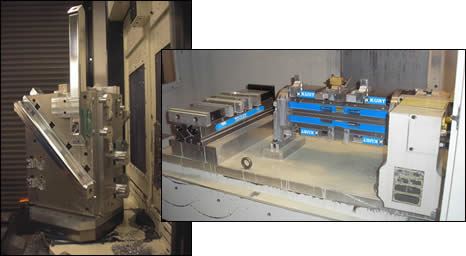

Automating on short runs is routine for Protofab. On its horizontal machining center, the shop uses the indexing fourth axis to machine as many features of the part as it can in one cycle, and it uses carefully engineered tombstone fixturing to machine an entire family of related parts all at once.

On a vertical machining center, the shop does the same thing—using an add-on rotary indexer to reach angled features and to set up an entire family of parts for machining all at once. On the right jobs, applying the vertical in this way can allow it to serve as a “poor man’s horizontal,” Mr. Maendl says, achieving much of the same effectiveness as an HMC at a lower rate of cost to the customer.

Machining the complete family in one cycle on a low-cost VMC is how the shop produced the various prototype implant parts efficiently. In short, this workholding strategy was one practice that did scale down.

Getting To Micro

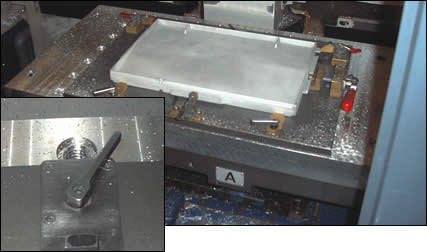

More typical work for Protofab includes parts at more conventional sizes—say, 1 or 2 square feet—for customers in the electronics and communications industries. Workholding innovation is often the key to meeting machining challenges. Some precise holding trays for a complex blood analysis machine (the shop’s first medical-related work) provide an example. The expansion of these parts during machining caused them to distort against the workholding clamps, leaving the machined features out of tolerance once the part was released. The shop solved this problem by creating a floating clamp (see photo below) that was free to shift slightly to accommodate the part’s expansion.

Protofab used the same kind of ingenuity to develop fixtures to hold and accurately locate the tiny implant parts. The indexer, combined with this workholding, provided both the ability to machine multiple angles in one cycle and the space to accommodate all of the fixturing for the entire family of parts in one setup.

With the workholding engineered and in place, all that remained for Protofab was to figure out how to machine at micro scales on a lower-cost machine.

It could be done. However, it turned out there was a lot to learn.

No One Can Hear You Crash

Down at 0.025 inch in diameter, you can’t easily see a tool break, says Mr. Krall. You can’t hear the tool cut. There is no feedback for the machinist until the part is removed from the setup. Only then does the machinist potentially discover that the part is out of tolerance, the burr is too big to remove quickly, or a piece of the cutting tool is still sticking out of the workpiece to testify that the tool did, in fact, break. After long hours of experimentation and more than a few frantic calls to the tool supplier after going through too many small tools too quickly, what follows is a taste of what Mr. Krall and Protofab have learned about machining effectively with tiny tools.

These lessons were learned during the prototype and pre-production machining—work that was performed on a machining center that was never intended to see such fine cutting. Some of the lessons (such as the speed) probably will not apply in full production, when the shop uses its new turning center. New lessons will come at that point, but Protofab expects this learning process to be much more of a graceful curve.

Mr. Krall says his first and perhaps most basic piece of advice is that machining at smaller scales requires a shop’s workbench to have a piece of equipment it probably does not have today—a microscope.

For inspection and deburring, Mr. Krall is peering through his microscope almost constantly as the implant work is being run.

A presetter becomes essential, too, he says. The tiny amounts of tool runout that the shop can live with on a 1-inch or 1/2-inch diameter tool become unacceptable at smaller scales, because that small value of runout becomes a huge percentage of the tool’s diameter. Without using a presetter to set tools precisely, tool breakage is practically guaranteed.

Here are other lessons the shop has learned:

The tool. On the low-cost VMC, a $2 micro tool made of high speed steel often works better at machining the hardened stainless steel implant parts than an $80 carbide tool engineered for high performance. That’s because the flexibility of the HSS tool is often essential to machining the feature in cases where the tool is subject to some small amount of play or imbalance in the process. The carbide tool facing less than optimal conditions is likely to break. Plus, the speed that the carbide tool can offer the shop is not important for such low volumes. The shop routinely runs the tiny tools not at the high spindle speed expected for small tools, but instead at 6,000 rpm. Cycle time is not what is important here, says Mr. Maendl. What is important is working out a process that reliably and precisely machines the feature.

The plan. Process planning is “tremendously important,” says Mr. Krall. The order in which machining operations are performed can determine whether those operations will succeed at all. One example involved a tiny hole drilled off-center into the OD of a cylindrical part. On a regular-sized part, the OD would be turned to size before holes were drilled into it. On this implant part, the shop left the extra OD stock in place so that it could mill a flat at the hole entry point. This allowed the drill to enter a perpendicular surface instead of a sloping curve. Before implementing this measure, the drill would deflect and break.

Deburring represents another significant reason for process planning. Deburring can actually be more costly and time-consuming than machining. When the VMC produces families of implant parts, it takes two operators performing deburring to keep up with the machine’s output. This is not a testimony to the machine’s speed, but instead a result of the difficulty of deburring down at tiny scales. A machining strategy that reduces deburring—for example, ramping the milling tool in and out of the cut to knock away most of the burr—can deliver significant time and cost saving to the process.

The machine. Protofab has demonstrated to itself and its customer that an expensive machine is not necessary for medical implant machining. In fact, when the part relates to a product under development that hasn’t earned any money for its sponsors yet, doing the work on an inexpensive machine may be essential. Part of the key is simply to know the machine well and know what it can do—and when the machine can do it. Mr. Krall says thermal drift of the machine can be ignored on almost all of the conventional-size work the shop does, but it becomes critical to manage the drift on the micro-machining work. The machining center has to be allowed to warm up for 45 minutes, he says. Then, for the next 2 to 3 hours, he checks parts frequently and makes repeated changes to CNC offsets to chase tolerances. This is simply the reality of using a machine such as this for fine work.

Step Up

Working this way will no longer be acceptable when the parts go into production. Hence the need for the CNC Swiss-type.

The implant part hasn’t fully ramped up into production yet, but Mr. Maendl says the shop is already receiving RFQs for Swiss-type work. This is comforting. He says it reaffirms one of his assumptions—that there is enough opportunity out there in small-part machining that it was worthwhile for the shop to take a big step in order to get there.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreRead Next

Get Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More