Medical

A Big-Picture View of Micromachining

Matrix Tooling makes injection molds for components that have features you cannot see.

Read MoreAdvancing Manufacturing, Tomorrow and Today

A drilling solution improves the production of a component that is critical for correcting spinal disorders. Meanwhile, an apprenticeship program ensures that improvements like this one can continue into the future.

Read MoreWireless Ballbar Speeds Medical Machine Testing

The QC20-W wireless ballbar from Renishaw enables this precision-machined medical device manufacturer to perform faster, more convenient CNC machine capability tests and produce a representative measurement of volumetric positioning accuracy.

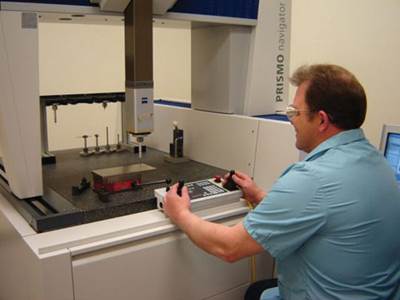

Read MoreCMM Outperforms Expectations

For this precision manufacturer, keeping inspections cost-effective required a system that could provide both high accuracy and reduced measuring times. The Prismo navigator CMM from Zeiss delivered both, along with additional, unexpected benefits.

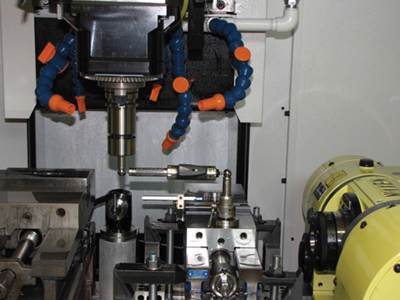

Read MoreLighted Workstop Verifies Part Location

Electrifying the work allows a light to indicate whether the setup is correct. The simple solution turned into a standard product for this shop.

Read MoreCAM System Tackles Swiss-Type Complexity

Partmaker CAM software helps this shop cope with the increased complexity of the medical parts processed on its similarly complex Swiss-type lathes.

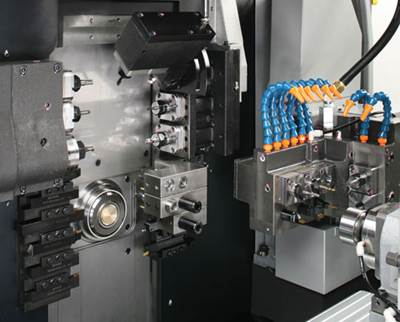

Read MoreCell Works the Night Shift

At this aerospace and medical component manufacturer, a Doosan HMC paired with a flexible pallet magazine and cell controller from Fastems has increased production and part quality while eliminating variation throughout the production chain.

Read MoreJob Shop Uses 3D Wire Bending and CNC Machining To Find Its Niche

Marshall Manufacturing melds CNC machining and 3D bending to create intricate medical components from small-diameter barstock and tubing. Customer needs spurred the shop to carve out what has become a successful medical-manufacturing niche.

Read MoreCAM System Simplifies Swiss-Type Lathe Programming

To reduce setup times, this medical device manufacturer replaced its conventional CNC turning and milling machines with Swiss-type lathes. However, taking full advantage of these complex machines’ capabilities required another investment—Esprit CAM software from DP technology.

Read MoreRecognizing the Swiss Advantage

A growing number of job shops have realized that multifunction Swiss-type lathes can make them more competitive. This Ohio shop explains how and why it integrated its first Swiss-types and shares some of what it has learned along the way.

Read More