Lighted Workstop Verifies Part Location

Electrifying the work allows a light to indicate whether the setup is correct. The simple solution turned into a standard product for this shop.

Share

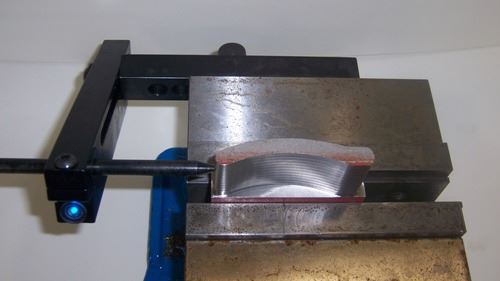

During setup, just the turn of a screw can make the difference between a sellable part and a scrapped one. A part that locates accurately can shift out of tolerance with the last twist of the screw that clamps it. The operator might not know this has happened until after the part is machined and fails inspection.

R&R Tool experienced this. The contract manufacturer in Blanchester, Ohio, specializes in precision medical components. A particularly challenging small and flexible part required an angled surface to locate with respect to a hole at the other end of the workpiece. This part might locate accurately against a workstop at first, but then was prone to shift invisibly during clamping. R&R had to find a way to reliably ensure that every clamping was accurate, without having to rely on tedious measurement, re-clamping and re-measurement for each setup of this part.

The solution that R&R hit upon was to electrify the workstop.

After all, the part was conductive. An accurate setup would therefore close a circuit—with a light indicating that this contact was made. The actual light the shop has been using is blue ... but seeing this light gives operators the green light to begin machining.

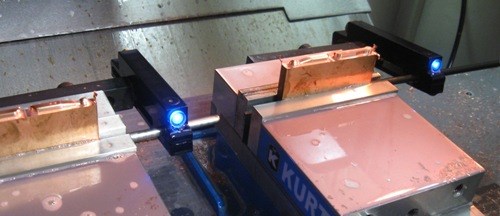

Shop owner Dan Reed says the solution has been so effective and so useful, his shop has begun using it as a routine element of making other parts as well. In addition, the shop has begun marketing the product. R&R now manufacturers and ships a self-contained version powered by AA batteries. The trade name is the “Lightnin’ Rod.” Various other shops have already found this new product and begun to use it.

A photo at right shows the Lightnin’ Rod being used on another R&R part. The components are machined four at a time out of two solid blocks. When the blocks gets small, the operator uses supports to raise them up out of the vise to get more pieces. Each of these new clampings creates an opportunity for error. The stock shifting by a few thousandths during clamping or during machining can cause a component to be scrapped. With the charged workstop, though, the stock must be within 0.0005 inch of the workstop for the light to activate. Therefore, the operator only has to see that the light is on for each vise prior to machining, and still on after the machining is complete. If so, then the parts are good.

“This is all about getting away from relying on the ‘feel’ of skilled machinists,” Mr. Reed says. In the past, the employee setting up this part would use a 0.002-inch shim to check that the work was close to the stop. However, there are problems with this approach. That “feel” is subjective, and investigating the setup in this way adds time to the process. Worst of all, the skilled employees who possess this kind of reliable feel are becoming scarce. The new process makes it possible to rely on less experienced employees for these parts, with the light serving as a concrete go/no-go gage for each setup. Mr. Reed says the shop is currently developing a variation on the Lightnin’ Rod that will work for non-conductive workpieces as well.

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreNavigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More