Medical

Five-Axis Machining Center for Dental Applications, Operated by Apple iPad

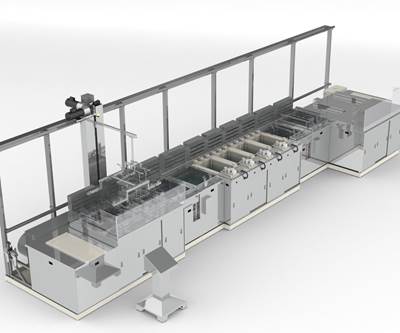

Datron Dynamics Inc. says the company’s D5 Dental Mill is a 5-axis, high-speed machining center designed for dental milling applications including crowns, bridges, abutments, inlays, onlays, telescopes, implants, bar work and even models. A rigid cast iron construction houses a fully-integrated 5-axis automation system built to hold up to eight material blanks or “pucks” frequently used by dental labs. This integrated eight-piece handling system loads and unloads blanks for unattended operation.

Read MoreVideo of a Really Cool Bar (-Fed Machining Center)

See a five-axis, bar-fed machining center creating a complex sample part complete from barstock.

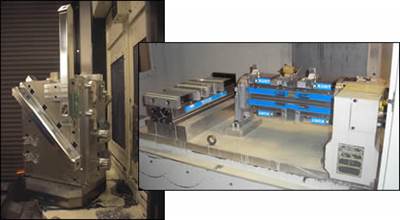

WatchHard Milling Isn’t Just High Speed Machining

Milling complex forms in hardened tool steel involves more than just fast, light cuts, says this maker of medical-related injection molds. Here are some of the ingredients of an effective hard milling process.

WatchPassivation of Stainless Steel Parts: The Recipe for Success

Passivation—the process for making stainless steel parts more corrosion-resistant—is affected by how well the part is cleaned. It’s also affected by the choice of acid. Nitric or citric?

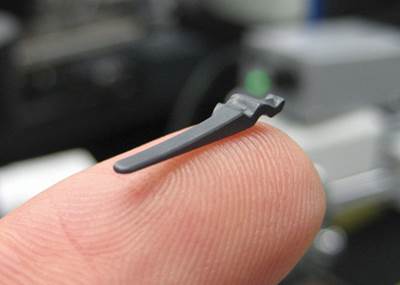

Read MoreIt Takes Firm Resolution To Master The Micro

This shop’s experience of successfully machining a micro aneurysm clip in silicon nitride ceramic points out the need to have CAD, CAM and CNC capability at high resolution—plus the commitment to pull it all together.

Read MoreSee The Tool's Value Instead Of Its Cost

This company is embracing high-performance tooling on its turning centers. The "sticker shock" is no reason not to do this. In one case, though, the shop found a way to limit the cost of the tool and increase productivity at the same time.

Read MoreBringing It All Together

Shops that serve medical instrument and implant manufacturers face special challenges. Their customers typically want precisely machined parts plus the extras such as finishing, marking, assembly and expert handling of the regulatory paperwork. That’s why this shop is focused on providing more than just the machining.

Read MoreConsider Swiss-Types For Medical Opportunities

Adopting the latest machining technologies is key for shops to accurately and repeatably create medical components. Swiss-style lathes offer a good combination of precision and repeatability for these applications thanks in part to their guide-bushing design, which provides support for the workpieces very close to the cut.

Read MoreEconomies Of Scale

Medical implant work is not just small in terms of workpiece sizes. Lot sizes and lead times can also be small when the product is still under development. To compete for implant work, this shop aims to offer cost savings in the face of all of this smallness.

Read More

.jpg;maxWidth=300;quality=90)