When C&A Tool first began producing medical parts on its Swiss-type lathes, the company typically programmed the machines manually on the shop floor. However, as the capabilities of these machines increased along with the complexity of the parts processed on them, it became clear that this strategy would no longer be feasible. Rather, the key to success would be to quickly and efficiently develop manufacturing processes—and by extension, NC programs—that push these complicated machines to reach their full potential.

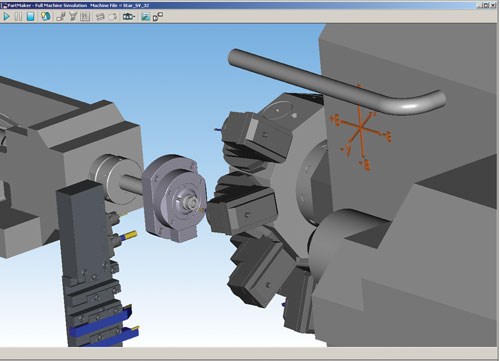

To that end, the company created a dedicated Swiss-type programming department and invested in CAM software from Partmaker (Fort Washington, Pennsylvania) to automate programming. That CAM system has since become the central nervous system of the shop’s Swiss-type business, says Nathan Esslinger, manufacturing engineer who is responsible for Swiss-type programming. “The job is made or broken in the process,” he says. “Partmaker’s been a big help in assisting us to develop that first process, simulate the part and obtain a better idea of whether that process will work.” He adds that the software has also improved productivity and made it easier to deal with a lack of qualified machinists.

Since its founding 40 years ago in a rural Indiana garage, C&A Tool has grown into a 530-employee organization occupying a campus of buildings with a total of 750,000 square feet of manufacturing space. Its main manu-facturing plant and headquarters is located in the northern Indiana town of Churubusco. Richard Conrow, C&A’s founder and president, says the company’s growth has been driven by a commitment to reinvest in the business and develop its employees. In fact, the manufacturer has grown an average of 20 percent per year for the past 25 years in terms of both personnel and company sales.

C&A’s Swiss-type operations are carried out on a bank of 27 multi-axis machines from Star CNC Machine Tool Corp. (Roslyn Heights, New York). Equipped with more than 12 programmable axes, these machines can perform 3D surface machining and use angled toolholders to cut inclined features, among other capabilities that weren’t available until relatively recently. “We don’t even call them Swiss lathes,” Mr. Esslinger says. “We call them Swiss machining centers because some of the parts we make on them don’t ever see a turning tool.”

The manufacturing process for these parts begins with importing an engineering design into Partmaker. Although C&A typically programs from solid models, the software accepts 2D drawings, as well. After importing the geometry, programmers assign machining operations in order to calculate the tool paths. During programming, the software employs a patented “divide and conquer” approach that involves breaking a complex part into individual face windows, each of which contains features being machined in a particular plane. For example, one window might be used to graphically program all turning operations on the machine’s main spindle, and another might be dedicated to C-axis milling operations with a horizontally oriented tool. Yet another window might contain a group of features machined with a vertically oriented Y-axis tool.

This approach makes it easier to cope with the increasing complexity of the shop’s medical parts. Additionally, it has made the company more productive, says Mark Simpson, the supervisor of the Swiss machining area. “We can take a complex part and program it in a couple of hours,” he says. “There is no way this could be done on the floor anymore.”

The company’s successful foray into medical parts has led to significant growth in its Swiss machining capacity. When it started this work in 2002, it had eight Swiss-type lathes, compared to 27 today. While plans for further expansion are in the works, growth has so far taken place against the challenging backdrop of finding skilled Swiss-type lathe operators, Mr. Simpson says.

One reason Swiss-type capacity continues to grow despite this lack of qualified personnel is that Partmaker makes it easier to do more with less, Mr. Esslinger says. That’s primarily a function of the software’s 3D simulation capability. Simulation enables programmers to closely evaluate a process before committing machining resources. Exact models of both the part and machine ensure that they can see precisely how operations will proceed and detect any collisions or other problems before setting up the job—all from a PC located away from the shop floor. “The more time you take with the software, running the collision detection, the less time you spend in setup,” Mr. Esslinger says. “An extra 20 minutes on Partmaker can save 8 hours on third shift in the middle of the night, when no one is here to help.”

With these capabilities, the company has reduced programming time by half, Mr. Esslinger estimates. Additionally, the company increasingly takes on jobs it would have turned away in the past. However, the software also provides benefits before a single tool path is programmed for any given part. By making the quoting process more efficient, the software enables the company to take on more jobs.

These time savings are partially due to the software’s knowledge-based machining approach, which stores data about commonly used tooling, materials, feeds, speeds and other commonly used parameters for reuse later. This capability enables the company to apply the machining expertise of its people from one job to the next. It also enables generating more accurate time studies for parts as a byproduct of the programming process. Using the software to develop time cycles for quotations ensures that any particular part is already programmed when the job is awarded. “When we get a solid model, instead of taking hours, quoting takes minutes,” Mr. Esslinger says. That’s important because as he points out, “You don’t get paid to quote.”

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)