Medical

Striving To Be Partners, Not Shops

The two divisions within this business machine complex parts for the medical and aerospace industries. So in that sense they’re shops. However, in order to grow with their customers, they realized they had to be more than just providers of good parts. They needed to serve as their customers’ manufacturing partners.

Read MoreManagers Make Clean Air Top Priority

These shops have made maintaining a clean shopfloor environment a top priority. With Reven Recojet-1 mist separators from Tecnara Tooling Systems, they have been able to do just that with virtually no investment in floor space or time-consuming maintenance.

Read MoreGet Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

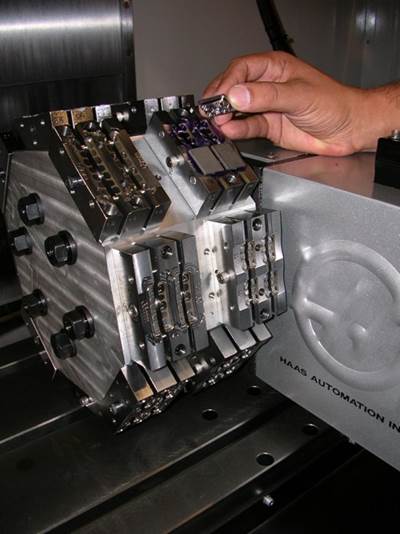

Read MoreSuccessfully Feeding The Medical Market

This medical shop has adopted five-axis, bar-fed machining technology to adapt to compressed delivery schedules and increasingly complex part geometries.

Read MoreA Quick Look At PEEK Machining

The use of PEEK polymer for medical implant devices is on the rise. A supplier of this material offers cutting tool tips for shops that may soon add PEEK machining to their list of capabilities.

Read MoreUnattended Machining Makes Oral Orthotics More Affordable

This shop makes the oral devices that helped the shop owner and members of his family. Unattended machining is the key to making this therapy more accessible.

Read MoreScrew Machine Shop Modernizes As It Moves To Medical

CAD/CAM software has been key for this shop to meet the tight lead times necessary to move into the medical market.

Read MoreUnder One Roof

In bringing multiple manufacturing processes in-house, this medical shop parallels its customers' efforts to be one-stop sources for hospital equipment.

Read MoreMachining’s Role In Making Cancer "History"

A machine shop in a new cancer treatment center produces components to precisely guide proton radiation to eliminate its target—cancerous tumors.

Read More

.jpg;maxWidth=300;quality=90)