One Way to Machine Long Titanium Parts

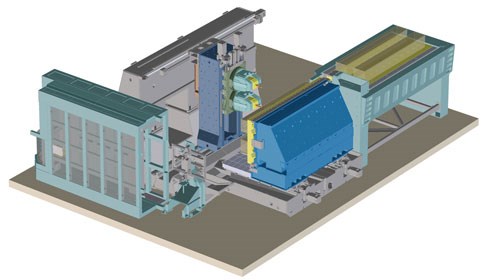

This horizontal machining center design not only addresses the need for larger machining capacity for long aerospace components, but it also offers impressive material removal rates for tough titanium alloys.

Share

Aircraft designers continue to replace high-tensile-strength aluminum alloys with titanium for key components. These include long parts such as engine suspensions and high-load primary structures in the wings and fuselage. Such components present machining challenges not only because of their material, but also because of their size. Some are more than 4 meters long.

Machine tool builders are developing large-scale machines to meet this demand. For instance, the Big Titanium Profiler (BTP) 5000 from StarragHeckert weighs 200 tons and offers 5 meters of X-axis travel. It is the largest and heaviest machining center the company has built. However, its design not only addresses the need for larger machining capacity for long aerospace components, but it also offers impressive material removal rates for tough titanium alloys. Tests have demonstrated that the BTP 5000 can achieve material removal rates of 46 cubic inches per minute in Ti 6Al4V and 18 cubic inches per minute in heat-treated Ti 5553.

The five-axis machine, which is available in single- or double-spindle versions, is an alternative to traditional multiple-spindle vertical mills. The horizontal spindle design enables chips to fall freely into the machine’s chip conveyor, which helps extend cutting tool life by minimizing recutting of titanium chips. In addition, chip removal is assisted by through-spindle coolant delivery at as much as 100 bar of pressure as well as a ring of coolant nozzles around the spindle(s). Plus, a fully enclosed machining zone enables better chip management than conventional multiple-spindle vertical mills.

The BTP 5000 has four axes of movement on the tool side, resulting in a frame structure that provides high static and dynamic rigidity. The pallet with workpiece moves only in the Z axis because of their combined enormous weight. The Z-axis slide floats via a stickslip-free, roll-recirculation system on stable, double guideways. Movement is provided by accurate servo motors and two ballscrew spindles with preliminary transmissions. This duplex layout of the drives and guideways (which also applies to the X and Y axes) provides the rigidity required for aggressive machining of titanium alloys, the company says.

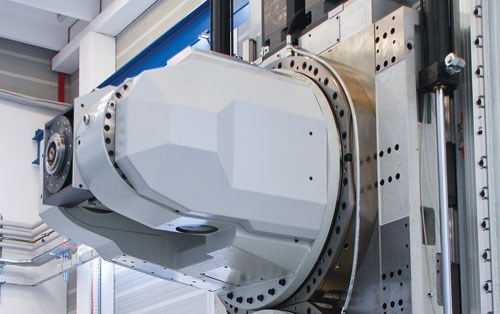

The swivel-head design provides ±100 degrees of rotation in the A axis and continuous rotation in the C axis. Hardened steel worm drives in both axes are said to ensure quality surface finishes and emit significantly less heat than a torque motor, meaning the worm drives minimize compensation required for heat generated during operation. In addition, both the A and C axes use large-scale, axial/radial cylindrical roller bearings that offer significant tilting resistance.

The BTP 5000’s gear-driven spindle provides a number of features that facilitate roughing and finishing operations in titanium. The single-spindle version offers 37 kW of power, 940 Nm of torque and 8,000 rpm. A modular ATC unit can provide 180 to 450 tool pockets (450 pockets are available for the two-spindle version). The tool changer is a double-gripper system, and both tools are changed at the same time on the double-spindle version.

An automatic pallet changer with two pallets enables 24/7 unattended operation. The BTP 5000 can also be integrated into a manufacturing cell with a pallet-shuttle and a master computer. The machine is equipped with the company’s Service Assistant Module, an on-board diagnostic system that helps users diagnose errors and understand complex machine functions.

Related Content

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreFive-Axis Machines Speed NASCAR Engine Production

Moving from an aging set of five-axis mills to more advanced machines enabled Hendrick Motorsports to dramatically improve its engine production.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More