Zayer Sizes Up the Large Machine Market

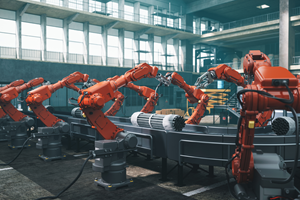

Republic Lagun Machine Tool Co. is promoting this line of traveling column machines to users in the wind turbine, airframe, oilfield and rail industries.

Share

Interest in large machine tools continues to grow in the United States and elsewhere in North America, especially because oversized workpieces are prevalent in the wind turbine, airframe, oilfield and rail industries. One machine tool builder active in these industry segments is Zayer, a company headquartered in northern Spain but represented in the North American market by Republic Lagun Machine Tool Co. (Harbor City, California). Although Zayer specializes in large CNC bridge- and gantry-type machines, it also offers traveling-column models.

Related Content

Forkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreSolar Atmospheres Receives Northrop Grumman Approval for South Carolina Facility

All five Solar Atmospheres facilities are now an option for customers with Northrop Grumman requirements for vacuum heat treating.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More