The 400° Difference

Cryogenic machining achieves dramatic tool life gains not by flooding the cut, but by refrigerating the tool.

In the mechanism of tool wear, the “wear” itself is not solely and specifically what causes a tool to fail. Temperature is the real enemy.

Because of temperature, a little bit of wear can feed on itself. That is, a slight dulling of the tool edge, because it increases friction within the cut, can cause the heat of machining to increase. The tool therefore becomes hotter, and the tool material softens—encouraging the cutting edge to degrade further and faster. More dulling leads to more friction, and so on. The tool fails in a self-accelerating curve fueled by the heat.

In fact, when the workpiece material itself is resistant to heat, this phenomenon is particularly pronounced. This very effect is why such materials as titanium, Inconel and compacted graphite iron (CGI) are all so difficult to machine. The condition that is needed most in these machining applications is cooling.

But the fluid we call “coolant” ironically has a spotty success at providing this. Flood coolant does draw heat out of the machining process, but it does so from a certain distance—unable to touch the actual place where heat is being created, namely the zone beneath the chip where the tool is shearing through metal. Through-spindle coolant tries to get the coolant closer to this cutting zone, and new developments in through-the-insert delivery bring the coolant very close indeed. These measures are frequently effective, and often significantly effective.

However, their success implies something further. Specifically, it implies that even greater tool-performance gains could be realized by getting the cooling mechanism right to the very point where cutting is taking place.

Machine tool supplier MAG believes the key to such cooling is not to be found in traditional coolant, but rather in the heat-absorption capacity of the tool itself. MAG seeks to increase this absorption. The company has introduced a new variety of cryogenic machining that not only has been proven effective in various challenging materials, but also is now available as a factory-installed option on most of the company’s machining center models. In various applications involving milling of titanium in particular, this cryogenic machining has been found to dramatically extend tool life, multiplying it by a factor of 10.

The system uses nitrogen. That in itself is not a new idea, but MAG’s patented method is different from previous approaches. Other applications of nitrogen cooling have involved submerging the entire work area in nitrogen or spraying nitrogen from an external nozzle. MAG’s approach, which was originally developed by R&D firm Creare Inc., might best be thought of as “minimum quantity” cryogenic machining. In this approach, liquid nitrogen flows through the spindle and through the tool at a low rate similar to that of minimum quantity lubrication, or MQL. Unlike MQL, however, the purpose here is not lubrication. The purpose instead is cooling. The purpose is extreme cooling.

That point is fundamental, says George Georgiou, a senior tool engineer with MAG who has been involved with cryogenic machining’s testing and development. He says this means of cooling represents a dramatically different way of thinking about metalworking fluid. In more typical machining, the fluid lubricates the cut and/or washes over the tool and part to carry heat away. By contrast, the fluid’s role in cryogenic machining is refrigeration. Flood coolant might be +70°F. The liquid nitrogen is -321°F—a difference of nearly 400°F. That difference is enough to turn the tool into a heat sink. Given the extremely low temperature, the tool is able to act as a thermal sponge, drawing the heat of machining away from the cutting edge and into the tool body so that the life and performance of the tool do not have to degrade prematurely.

Performance Difference

MAG has been working on this low-flow version of cryogenic machining for nearly 4 years. Much of the development work has been in cooperation with defense aeronautics company Lockheed Martin. Now, MAG can provide spindles engineered to deliver cryogenic fluid on any of its three- and four-axis machining centers, with the availability for five-axis machines coming soon, says Mike Judge, business development manager of MAG’s cryogenic machining technology.

On any of these machining centers, liquid nitrogen from a storage tank flows through the spindle and through a specially insulated tool. MAG provides tooling by modifying standard cutting tools from its Cyclo Cut line. The company says various types of tools from this line can be used in the process. For example, while carbide tools have been applied to most heat-resistant workpiece materials, the company says PCD tooling has proven the most effective for cryogenic machining of CGI.

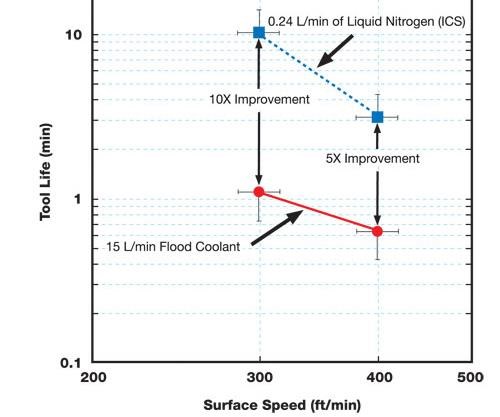

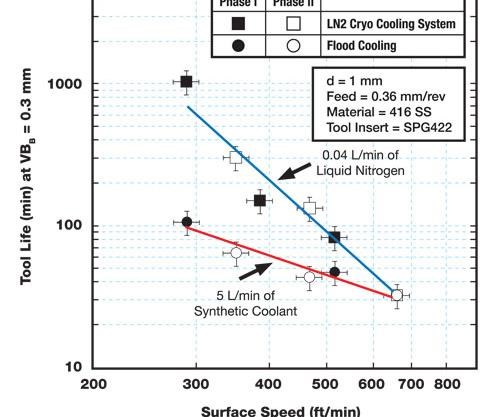

Graphs at right quantify some of the performance benefits of liquid nitrogen cooling. In titanium, a tool running at 300 sfm (aggressive for this material) wears out after 1 minute under flood coolant, but reliably lasts for 10 minutes when refrigerated, as shown in the first graph above. The same tool delivers a 5-factor performance gain when the speed is faster. Mr. Georgiou says the area between these two performance plots maps the productivity difference between the cooling approaches. Working within this area, the user of flood coolant who switches to cryogenic machining can choose either greater speed with the same tool life, or greater tool life at a given speed.

No Slip

The two performance plots eventually converge, he notes. The difference in performance between cryogenic machining and conventional flood coolant machining is greatest at lower speeds, narrows at higher speeds, and disappears altogether at some speed that is very high. In the test of stainless steel shown above, cryogenic machining delivered 10 times better performance at just under 300 sfm, gradually narrowing to 4 times better performance under 400 sfm and showing no performance difference at about 650 sfm.

Yet even setting aside the cutting performance differences, there are still other factors that argue in favor of the cryogenic approach, says MAG. One surprise for the MAG team (which had been focused on those performance improvements) was the amount of interest in cryogenic technology’s potential benefit to employee safety. After cryogenic machining, there is no slippery fluid left covering the surfaces of the machine. As a result, in large-machine applications—that is, in applications where operators sometimes have to walk onto the table of the machine tool—the risk of the operator falling is reduced.

Another set of benefits relates to the natural environment. Rather than using a manufactured fluid for cooling, cryogenic machining simply uses nitrogen, a substance that is taken from the natural air and given back to the air. No fluid disposal is needed. Nitrogen cannot contaminate the air, and additionally cannot contaminate medical components or other sensitive workpieces.

Finally, Mr. Georgiou points out that cryogenic machining also has lower power requirements than traditional flood coolant machining. While flood coolant needs power for pumps and filtration, the only power requirements in the liquid nitrogen system relate to extracting and compressing the nitrogen—work that is likely to be done by a liquid nitrogen supplier delivering a filled tank.

Cost per Cube

MAG says machining facilities today can test cryogenic machining on their current machine tools. The company offers a test kit including a toolholder with a liquid nitrogen line (see photo). The kit does not provide for a perfect test, because putting cryogenic delivery within the toolholder adds to the overhang length and compromises the rigidity of the setup. However, the kit should be enough to let prospective users determine just how much savings from cryogenic machining they are likely to see.

Significant tool life savings are obtainable today. Meanwhile, Mr. Georgiou says the resulting savings in tool cost are going to continue to get better. He sees tooling as the most significant area where the cryogenic process still has to improve. Today, because the user base is small, off-the-shelf tools are modified as needed for cryogenic users. In the future, a catalog of tools will be engineered, manufactured and stocked for this application—bringing tool prices down.

Yet even today, the performance gains from cryogenic machining are potentially high enough to make the tool is inexpensive in relative terms. If the expense of a tool is measured in terms of cost per cubic inch of material removed, then Mr. Georgiou says he expects cryogenic machining will eventually permit the lowest-cost cutting edge that the industry has ever seen.

Related Content

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreRead Next

Video: Cryogenic Machining of Titanium

Through-tool liquid nitrogen turns the tool into a heat sink, extending tool life.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read More

Dan Cooper is product manager for MAG’s Cyclo Cut cutting tool line. He sees cryogenic machining fitting into a larger context. The liquid nitrogen system addresses the fact that heat is the real challenge of machining high-temperature materials—but this challenge is nothing new. Tool designers focused on these materials have always recognized that heat management was the concern. Even without refrigerating the tool, there are engineering considerations that can dramatically improve tool performance by preventing heat from accumulating within the cutting edge.

Dan Cooper is product manager for MAG’s Cyclo Cut cutting tool line. He sees cryogenic machining fitting into a larger context. The liquid nitrogen system addresses the fact that heat is the real challenge of machining high-temperature materials—but this challenge is nothing new. Tool designers focused on these materials have always recognized that heat management was the concern. Even without refrigerating the tool, there are engineering considerations that can dramatically improve tool performance by preventing heat from accumulating within the cutting edge. Is nitrogen safe?

Is nitrogen safe?

.jpg;maxWidth=300;quality=90)