Aerospace

Eliminating Tool Pullout in Titanium Milling

Toolholder employs a secondary locking system to counter the high axial cutting forces encountered during the development of a tool for high-metal-removal-rate milling of titanium.

Read MorePresetting Becomes Prevalent

Next Intent implemented presetting and shrink-fit toolholding when it bought a five-axis machining center, but it has since seen these resources deliver value to machining centers throughout the shop.

Read MoreSlideshow: Vibration Isolators

An aerospace shop shows further examples of complex machined parts used to mitigate vibration.

Read MoreLaser Encoder Feedback for 40-Meter Wing Parts

Large machine travels, long machining cycles and changing aircraft manufacturing precision demands necessitated a non-contact approach to machine-tool position feedback.

Read MoreWhen to Waterjet, When to Mill

A composite parts manufacturer in Nebraska recently installed a combined five-axis waterjet/milling machine to position itself to win large-scale aerospace work it sees on the horizon.

Read MoreSetting the Stage for Sizeable Composites Work

By adding a five-axis waterjet/milling machine, its biggest autoclave and a more expansive lay-up room, Royal Engineered Composites is positioning itself to win larger-scale aerospace work it sees on the horizon.

Read MoreAn Electrochemical Option for Blisks, Blades

This machining platform offers the non-contact electrochemical/precision electrochemical processes for five-axis milling of turbine engine blades and blisks.

Read MoreTRAM Returns to IMTS 2014, Keynote Speakers from Boeing

The targeted aerospace conference takes place September 10-11, 2014, and will kick off with a presentation from the Vice President of Research and Technology at Boeing.

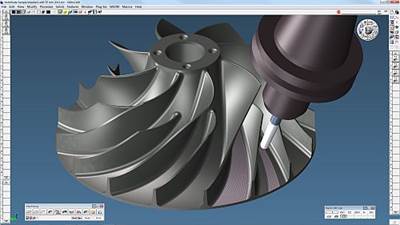

Read MoreA “Shortcut” for Bladed Components

GibbsCAM offers two options designed to simplify the programming of bladed workpieces such as blisks and impellers.

WatchWhat’s Best for Boring Titanium?

In a joint research effort, Kaiser Precision Tooling and Blaser Swisslube searched for a combination of metalworking fluid and indexable insert that show the best results when boring titanium. The results underscore the importance of controlling vibration, friction and heat.

Read More

.jpg;maxWidth=300;quality=90)