A “Shortcut” for Bladed Components

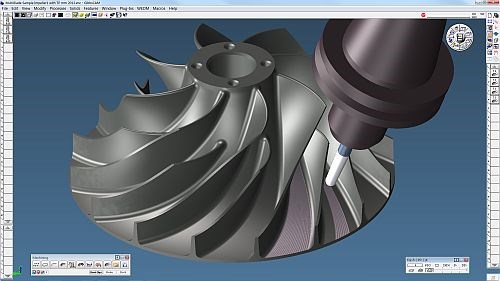

GibbsCAM offers two options designed to simplify the programming of bladed workpieces such as blisks and impellers.

Share

Industries like aerospace and automotive depend on bladed components such as impellers and blisks, but these workpieces can be complex and time-consuming to program and machine. Gibbs and Associates’ MultiBlade options for GibbsCAM provide a simplified user interface optimized for working with bladed workpieces within the GibbsCAM environment.

Two levels are available, depending on the type of work or level of specialization required. Level 1 covers workpieces with single splitters, and Level 2 can be added to support multiple splitters, sub-splitters, blade fillet machining and other advanced features.

Watch the video above, produced by Gibbs and Associates, for an overview of the MultiBlade functionality in GibbsCAM.

Related Content

-

Grob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

-

Increasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

-

Horizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

.jpg;width=70;height=70;mode=crop)