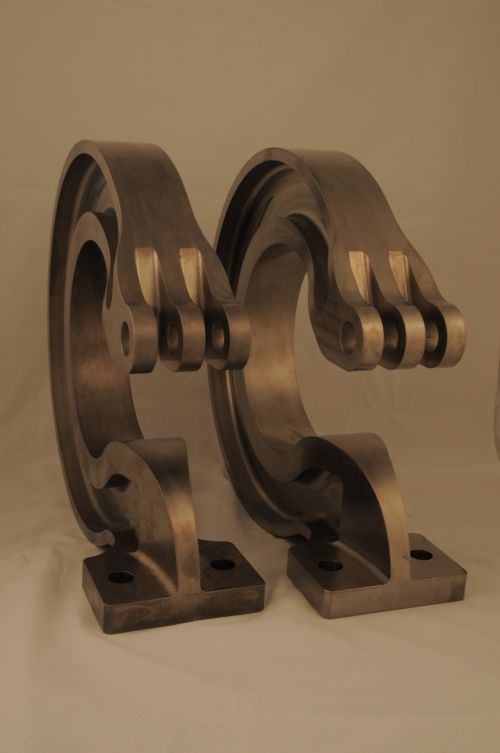

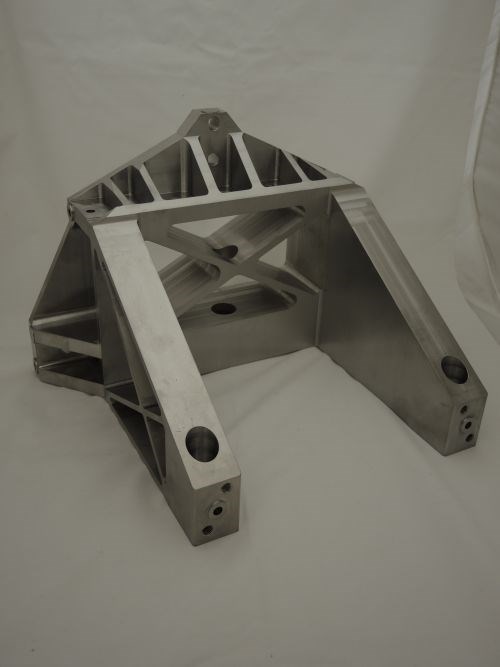

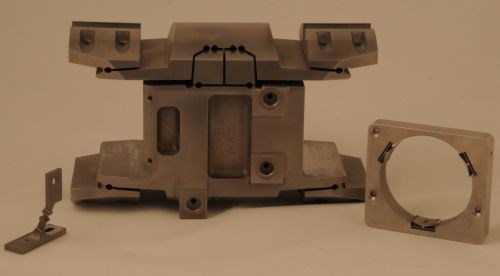

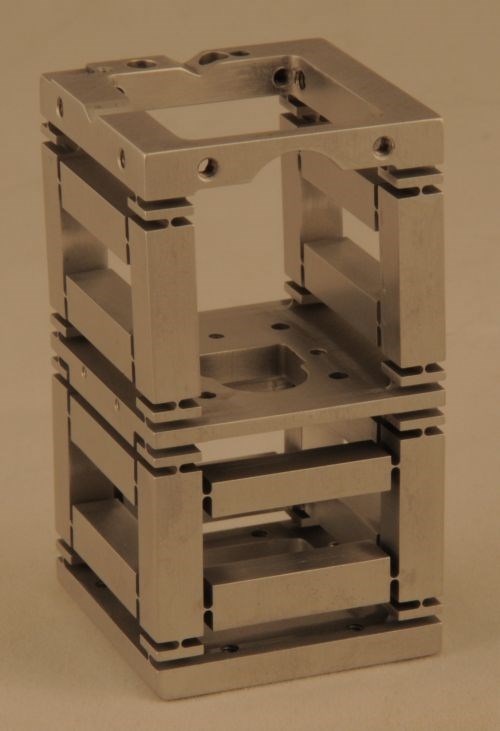

Slideshow: Vibration Isolators

An aerospace shop shows further examples of complex machined parts used to mitigate vibration.

Share

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

In this article, aerospace manufacturer Next Intent discussed the challenge of machining vibration isolators, parts used to protect sensitive equipment during a rocket launch. As the article describes, part of the challenge in machining these parts is charging the right price for such complex work. Here from Next Intent are additional photos of vibration isolators the shop has successfully machined.

Related Content

-

Horizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

-

Arch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

-

Bavius Technologie Appoints New President, Schedules Technology Showcase

Roy D. Cripps will lead the team at Bavius as it aims to expand its current business in aerospace structures and develop new market segments. Additionally, the company will showcase its technology during an open house event on June 11.

.png;maxWidth=150)