Eliminating Tool Pullout in Titanium Milling

Toolholder employs a secondary locking system to counter the high axial cutting forces encountered during the development of a tool for high-metal-removal-rate milling of titanium.

Share

Toolholders for machining centers tend to work by compressing a cylinder around the shank of the tool. That is the case with either a collet holder or shrink fit. In either case, the weakness of this mechanism for toolholding is in the tool’s axial direction. Along this direction—that is, along the Z axis on a three-axis machine—the only thing restraining the tool is friction with the collet or the bore of the holder. If the Z-directed cutting force reaches a high-enough level, the tool can slide within the holder’s grip.

Technicut, the U.K.-based cutting tool supplier, routinely achieved that high cutting force in its development of an end mill engineered for aggressive cutting in titanium. Cutting forces pulling along the Z axis could cause its new tool to minutely slide within the holder, changing the gage length of the tool mid-cut. Toolholder supplier Nikken was brought in to help solve this problem, and the two companies worked together within the Advanced Manufacturing Research Centre of Sheffield, England. Stephen Eckersall, group engineering manager for Nikken, says the result of this work—the X-Treme Multi-Lock Milling Chuck—is the company’s first new product to have been researched, developed and tested in Europe prior to final design and production in Japan.

An existing holder was the starting point of the development work. Nikken’s Multi-Lock uses a clamping ring with precision rollers to compress the toolholder’s bore. The result is a strong, concentric grip with favorable damping characteristics, albeit still subject to the same tool-sliding limitation as other toolholders when the cutting force is extreme.

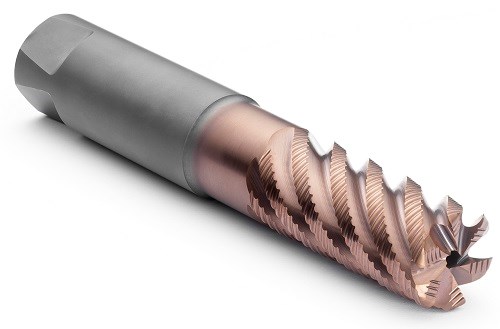

For those extreme cuts, the U.K. group added a secondary, complementary locking system that relies on modifications to the end-mill shank. Two screws press against angled flats on the tool shank to wedge the tool against a stop. The mechanical leverage of this now-patented system, the “X-Treme” clamping, has proven sufficient to prevent the tool from changing position in the holder in even the most aggressive cuts Technicut has taken with its new “TiTan Rippa” tool.

When the new tool and new holder are used together, says Mr. Eckersall, the performance difference is audible. The stability of the holder’s grip on the titanium-cutting end mill is such that cuts in titanium are quiet, even at high metal removal rates. (Go here to see and hear video of a 16-cubic-inch-per-minute cut in titanium 6-4.)

The difference is also measurable, he says. One aircraft-industry manufacturer has adopted the new tooling combination for milling slots in several sizes of titanium engine fan disc. The improvement in metal removal rate from this tooling has reduced the cycle time for one such part from 36 hours to around 11 hours. Meanwhile, the system’s stability contributes to tool life savings that have decreased the number of tool change-outs, so that only six milling tools now do the amount of machining for this part that used to require over 30 tools.

As of yet, the new Nikken X-Treme holder is available only for titanium. It is being sold with the Technicut end mill as a system for titanium milling. Mr. Eckersall says the next step is likely to be Inconel. The holder is currently being used in test cutting that is evaluating a new high-metal-removal-rate tool for the nickel-based alloy.

Related Content

Machine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreAFRC, ATI Partner to Boost Aerospace Materials Innovation

ATI Inc. has joined the University of Strathclyde’s AFRC as a tier one member, aiming to develop metallic alloys that support sustainability in the aerospace sector.

Read MoreKennametal Turning Tools Enhance Small Part, Medical Machining

TopSwiss Micro Boring Solid tooling and KCU25B turning inserts are well suited for the small parts and medical machining space.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreRead Next

Video: Quiet Heavy Milling of Titanium

During test cutting with a new tool-and-toolholder combination for titanium, this video was shot to record the sound (or lack of sound) from a deep milling pass.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)