-

SPONSORED

-

-

-

-

-

MMS Blog

Better HSM For Big Parts

'High speed machining' is accepted and commonplace in many shops. HSM is so widely used, in fact, that its acceptance is beginning to affect the design of machine tools.

Read MoreWhy Use Hydraulic Toolholders

The book on hydraulic toolholders is that they are fussy to set, fragile to operate and expensive to buy. So why do many shops choose them over other holders that seem less demanding? This Chicago mold builder has good reasons for its choice.

Read MoreInserts For Difficult Materials

Economic efficiency is an important consideration when choosing tools for challenging metals.

Read MoreStrong Medicine For Growth

A New Jersey shop that specializes in medical work combines the latest hardware with innovative software to gain a competitive edge.

Read MoreThe Hidden Costs Of Cutting Tools

This shop brought the hidden costs down by paying close attention to tool inventory.

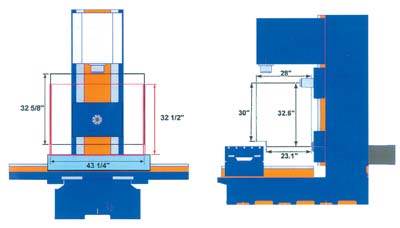

Read MoreSplit Personality

At the Canadian Machine Tool Show in late 2001, this company introduced its new H/V machining center. H/V stands for horizontal/vertical. OK, so it's a universal machining center ... big deal.

Read MoreWire EDM Gets An Automatic

The development of automatic 'tool' changing for wire electrical discharge machining promises to revise the process strategies applied to many wirecut workpieces.

Read MoreVolume III, Issue I

Pay Attention As this issue of MMS goes to press, there are economic-based initiatives pending before our federal legislative bodies that all manufacturers should be aware of. These are not “bail-outs” like those pushed through to benefit the airline industry.

Read MorePorous Steel Improves Mold Venting

Entrapment of gases during plastic injection is a problem that continues to challenge the design capabilities of moldmakers. The increasing complexity of tooling demanded by today's manufacturers dictates that many areas inside molds are quite difficult to vent adequately.

Read MoreMerging Functions For Better Efficiency

By eliminating extra steps, a multi-process machine enables a medical manufacturer to streamline its production time and conserve shop space.

Read MoreMulti-Station Repeatability Enhances Quality For Complex Parts

Flexible automation is making production machining a new opportunity for shops that traditionally did not seek this kind of work. At the same time, automated machining systems are taking new shapes and configurations that favor this trend. A recently introduced example is the Turn 6 LC from ATS.

Read MoreOne Stop Milling, Drilling, Turning And Grinding

Many shops, in an effort to reduce the handling of workpieces and get takt times (time spent in the cut) as low as possible, are looking to streamline this traditional hurry-up-and-wait process scheme.

Read More