One Stop Milling, Drilling, Turning And Grinding

Many shops, in an effort to reduce the handling of workpieces and get takt times (time spent in the cut) as low as possible, are looking to streamline this traditional hurry-up-and-wait process scheme.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Conventional metalworking practice suggests that processing hardened, precision, parts-of-rotation should be done in proper order. Blanks are first cut to length. Next they are loaded into a turning center and turned down to a point where "grinding stock" remains. Depending on the part, there may be an intermediary stop at a machining center. From the lathe and mill, these parts, now accounted for as work-in-process, go to heat treat for hardening. When they get back, it's off to the grinder for completion.

Many shops, in an effort to reduce the handling of workpieces and get takt times (time spent in the cut) as low as possible, are looking to streamline this traditional hurry-up-and-wait process scheme. One popular method has been to hard turn and/or hard mill the workpiece. Starting with pre-hardened stock and a rigid turning center and machining center, hard turning/milling allows shops to throughput work directly from the lathe and mill to the grinder. It bypasses the heat treat step.

In production, the challenge comes in matching the output of turning centers and machining centers to the processing capacity of grinders. Generally, it takes more grinders to keep up. So a shop either puts in a bank of expensive grinders or lets the process run unbalanced, in which case the WIP bogey rears it head.

Enter an unconventional approach to processing hardened, precision workpieces. It is represented by a machine tool design called Hardpoint. Developed by Erwin Junker Machinery, Inc., the machine concept looks at combining different, stand alone machining operations onto a single platform. In a nutshell, the idea is to handle a pre-hardened workpiece blank once and get a complete turned, milled, drilled and ground part—ready to ship—out at the end of the cycle.

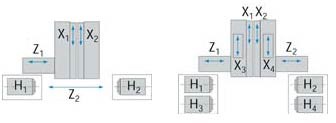

Junker builds grinders. The Hardpoint design starts there with a rigid base and tool carrier. The machine has a fixed main and movable secondary spindle. The secondary spindle is able to directly pick-off from the main to perform back-working operations.

Impetus for the Hardpoint concept came, as is so often the case in metalworking, from an application. The parts needed to be turned, bored, reamed, drilled and face ground. The tolerances for the face grinding operations were tight—the flat and parallel callouts were under 10 microns print tolerance. The CPK was pegged at 1.67 standard.

As the application engineers wrestled with reducing grinding cycle time and the number of machines needed for production, they began to formulate the idea of combining separate operations onto one machine. Keeping the parts on one machine immediately solved a big concern for this application, namely, tolerance stack-up error. If the conventional processing sequence of turn, mill and grind was used, each part would need to be qualified and oriented perfectly on the grinder to meet the final size tolerance. For several millions of parts a year, that's a bunch of handling.

A set of gang-type tool carriers was designed and fitted with turning tools, live milling cutters, and an innovative grinding head that does double duty for drilling. An independent gang tool carrier services each spindle. The gang tool holding platform gives flexibility to change the tooling scheme as needed.

Moreover, the concept is modular and can be scaled up to accommodate four main spindles. With that flexibility, the machine can be set up to run one or two parts complete, or it can process two or four parts at once. For applications that need multiple operations, combining them on one machine instead of moving them around the shop may be worth consideration.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.png;maxWidth=300;quality=90)