Wire EDM Gets An Automatic

The development of automatic 'tool' changing for wire electrical discharge machining promises to revise the process strategies applied to many wirecut workpieces.

Share

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreThe development of automatic "tool" changing for wire EDM (electrical discharge machining) promises to revise the process strategies applied to many wirecut workpieces. This trend is already apparent following the introduction of dual-wire machines by Agie Charmilles Technologies (Lincolnshire, Illinois). These models, the Robofil 2030SI-TW and the Robofil 4030SI-TW (the TW designation stands for twin wire) are reportedly the first wire machines with the capability to change from one size wire to another automatically. "Slugless" machining, for example, becomes a more attractive option.

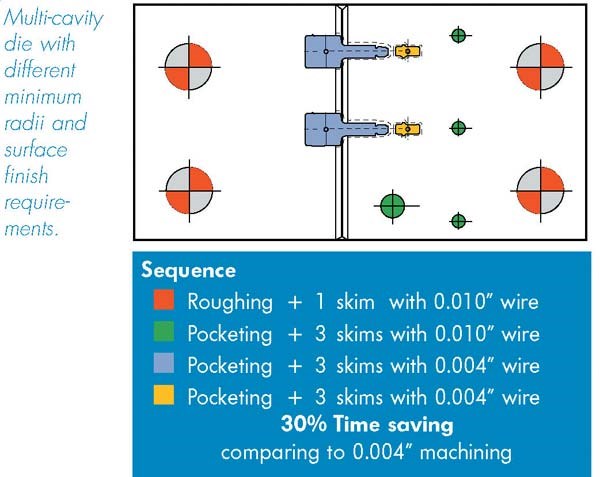

An EDM wire of a larger diameter (0.010 inch would be typical) is used to remove all of the material in an opening as a kind of roughing operation, where the wire follows a path similar to a pocketing routine in milling. This roughing procedure does not produce the slug usually created when the wire follows only the outline of the portion to be removed. After roughing out the opening, a finishing operation follows with a wire of a smaller diameter (0.004 inch perhaps). The smaller wire is used to produce sharper corners, reach a tighter dimensional accuracy and achieve a finer surface finish with additional skim cuts.

According to GFAGIECHilles, implementing this strategy on its dual-wire machines typically saves from 30 to 50 percent of the time normally taken, depending on the application.

Without automatic wire changing, openings could be cut with the large-diameter wire, then recut with the small wire after a manual wire change. For workpieces with numerous openings such as a lead frame die or multi-cavity mold component, manual wire change time adds up to a significant part of total process time. Another possibility is to cut all of the openings with the smaller wire. This approach minimizes loss of precision during manual wire changing and re-alignment. However, cutting speed is proportional to wire diameter, so the cutting time for the fine wire is considerably longer and the operator must be prepared for timely slug removal. Either of these scenarios rules out prolonged unattended operation, the mode in which EDM operates most economically. Both scenarios are also likely to keep the workpiece in water longer than the dual wire approach, increasing the risk of corrosion.

The dual-wire machines are equipped with two separate wire circuits located side by side on the front panel to bring the two wires down to the upper head guiding zone. Changeover from one wire to the other takes about 45 seconds and occurs without operator intervention. Each machine's on-board CT-Expert system automatically generates the machining parameters and tool paths for both wires, selecting the correct wire and wire settings for each programmed wire switch.

The Robofil 2030SI-TW handles workpieces as large as 1,130 by 510 by 260 mm (44.4 by 20.0 by 10.2 inches) and weighing as much as 500 kg (1,100 pounds). The Robofil 4030SI-TW handles workpieces as large as 1,150 by 725 by 360 mm (49.2 by 28.7 by 14.2 inches and weighing as much as 800 kg (1,765 pounds). Both machines can accept wire spools weighing as much as 55 pounds.

Related Content

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)