Split Personality

At the Canadian Machine Tool Show in late 2001, this company introduced its new H/V machining center. H/V stands for horizontal/vertical. OK, so it's a universal machining center ... big deal.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreAt the Canadian Machine Tool Show last fall, HH Roberts Machinery (Mississauga, Ontario, Canada) introduced its new H/V machining center. H/V stands for horizontal/vertical. OK, it's a universal machining center: big deal.

Well, true it can technically be called a universal machining center because it can cut from either a horizontal or vertical spindle orientation. It does, however, approach its "universalness" from a different direction. The direction is different enough to qualify for a U.S. patent.

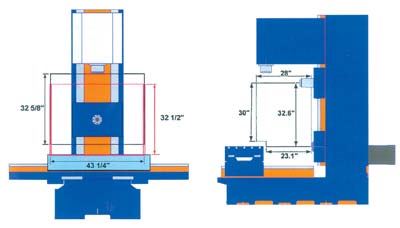

Essentially the difference in HH Roberts' machining center design is it carries independent vertical and horizontal spindles (each rated at 15 horsepower) on a common set of ways, mounted to a single column. The design allows both spindles to cover a generous work envelope and, with a rotary indexer mounted on the worktable, provide five-sided machining capability in a single setup.

With both spindles on the machine centerline, the full X-axis travel is available to each. This is key to work zone coverage. Travel on the show machine is 43 by 22 inches for its X and Y axes. The vertical head travel is 32 inches, as is the horizontal head. The design is scalable with 50- and 60-inch X-axis travel models due to be introduced soon.

The H/V is designed for job shops. Virtually every metalworking business is trying to get cost out of its process. Job shops are no exception. Five-sided machining in a single handling is one quick method to increase throughput by eliminating work-in-process.

In operation, the machine is only slightly different from a conventional vertical machining center. Programming conventions universally accept that the Z axis is parallel to the axis of spindle rotation. So for programming purposes, going from one spindle to the other changes the designation of the Y and Z axes.

The horizontal spindle is programmed in the same manner as a vertical machining center. On this machine, the Z-axis feed is accomplished by moving the worktable toward the column. A 6-inch positioning quill on the horizontal spindle allows use of optimum length tooling to access the side of a workpiece.

The machine uses an Anilam 5400 or 5500 CNC, depending if the machine is equipped for full five-axis or four-axis machining. Anilam wrote custom software for this unique machine configuration that automatically swaps the axis coordinates when switching from vertical to horizontal spindle. When this happens, tool offsets are automatically applied to the horizontal spindle. A mobile console-mounted CNC is available for the H/V that can be positioned in front of the machine for vertical processing and behind the machine for horizontal machining, which is generally preferred.

A 20-tool capacity automatic tool changer is available for the vertical spindle and was shown on the show machine. In its simplest form, the horizontal spindle is hand loaded from an access door behind the worktable. For more tool capacity, several tool changer configurations, up to 60 tools total, are available. The larger unit is designed to supply both spindles from its magazine.

Having the option to cut workpieces with either the horizontal or vertical spindle or both extends the processing capability of the job shop. While the company admits the machine is not designed to replace high tolerance horizontal machining centers, it will produce parts to general commercial tolerances of just under a thousandth of an inch at an economical price.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)