Concentric Clamps Hold Down Setup Time

A problem for many shops is that workpiece blanks vary from one to another. This is especially true with molded part blanks such as castings and forgings. These variations require some flexibility from the workholding device.

Share

How a workpiece is positioned for the machining process has a critical influence on the quality and output of the machine tool. There are as many ways to hang on to a workpiece as there are workpieces. Workholding variety notwithstanding, there are some basic commonalities in any attempt to properly secure a workpiece blank to a machine tool.

The goals of holding a blank include trying to provide maximum access of the cutting tool to all surfaces and features of the work. At the same time, the work must be held securely enough not to fly across the shop when a cutter engages it. Moreover, the clamping forces on the workpiece should be such that warping and deformation are minimized.

A problem for many shops is that workpiece blanks vary from one to another. This is especially true with molded part blanks such as castings and forgings. These variations require some flexibility from the workholding device.

Traditionally, these parts are clamped on the contour of the part blank. Because of the variations in the blanks, this method can lead to inaccurate positioning or increased setup time to locate the part and comp the machine tool.

Carr Lane Roemheld (St. Louis, Missouri) has developed a new concept to help shops deal with castings, forgings and sintered part blanks. They call the system concentric clamping. The idea is to bisect the workpiece blank using an imaginary line. Instead of locating off the contour of the part, this system locates off the centerline of the workpiece.

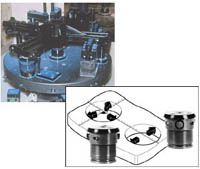

The clamping elements are modular, composed of passive and active components. The active modules are actuated hydraulically and can be operated from the machine hydraulics or an independent hydraulic pump.

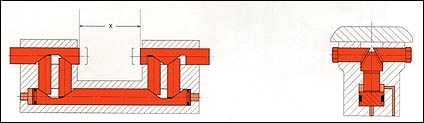

Two active designs are available with this system. A linear clamping element holds work on the OD with sliding clamps, much like a vise. A round concentric clamping element is used to grip on the ID of a hole or cutout on the workpiece blank. Standard clamping range for these ID elements is from 1 to 10 inches in diameter. The round clamps are made with two or three-way elements for location or centering as needed. Repeatability of the two and three point round elements is +0.0008 inch and for the linear units is +0.0002 inch.

Both the linear and round clamps operate using a “sliding dog” mechanism. With this device, the moving elements of the clamp slide on precision machined inclined planes. With hydraulic actuation of the moving elements, the hydraulic pressure causes the moving clamps to extend equally. Clamping force ranges from 200 to 15,000 pounds of force. This is key to the repeatability of the system. It also gives the holders sufficient stroke to accommodate variations between workpiece blank locating surfaces.

This system is designed for medium to high production volumes. Fixtures can be designed with routed manifolds or conventional hydraulic tubing. Palletized systems can use a de-coupling unit for portability in cells. The modules are reusable from one fixture to another.

For shops looking to improve the positioning accuracy of castings, forgings or sintered blanks, concentric clamping is a way to assure better accuracy from a fixture. Its ability to be automated also takes human error out of the equation.

Related Content

Prioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)